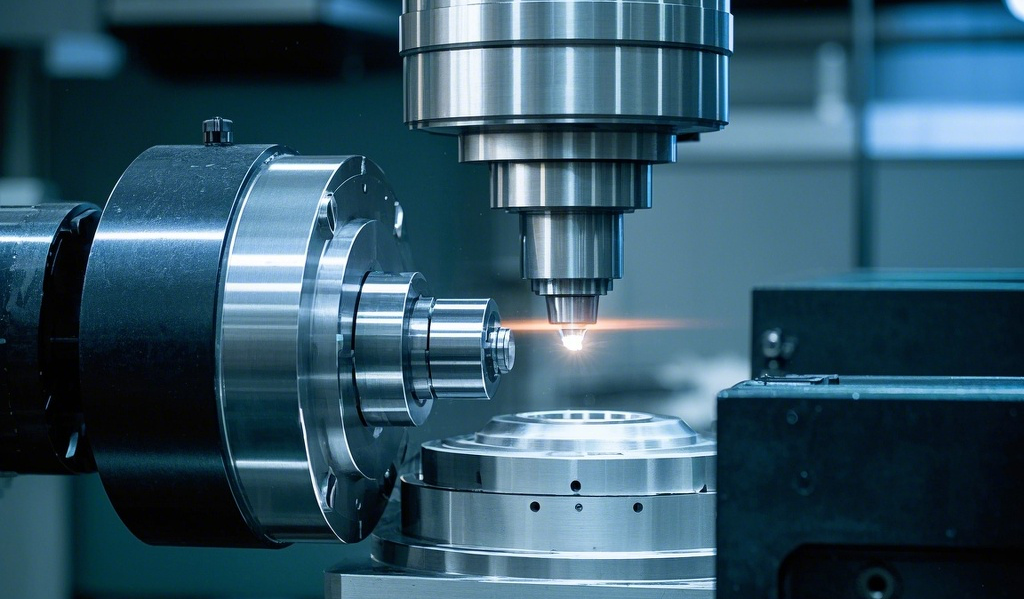

CNC machining has become a mainstream industrial manufacturing method due to its advantages such as high flexibility and precision. During product manufacturing, manufacturers may employ one or more machining processes, including CNC turning and CNC milling.

The CNC turning process involves removing material fragments as the workpiece rotates relative to the cutting tool. This article provides a comprehensive overview of the turning process, including its machining procedures, machine types, and applications.

First, let’s clarify the definition of CNC turning. Also known as computer numerical control turning, it is a classic subtractive manufacturing process that uses cutting tools to remove material from the exterior of a workpiece. The workpiece rotates while the tool removes material until the desired shape, diameter, and dimensions are achieved.

Unlike milling, where the cutting tool rotates, in turning, the workpiece rotates while the cutting tool (typically a single-point tool) remains stationary.

CNC lathes are suitable for turning various materials, including metals, wood, plastics, and other polymers. Since this process relies on computer-generated programs and codes, it ensures high dimensional accuracy, which is one of its key advantages.

While CNC turning may seem complex, once the CAD file is converted into a machine-readable program, you only need to set up the machine and initiate the turning process.

The process involves:

Rotating the workpiece while the cutting tool removes material from its exterior.

Typically, the material is cylindrical or round, but with compatible adapters, turning can also process differently shaped workpieces.

As the workpiece rotates, the cutting tool continuously removes material until the programmed shape is achieved.

Notably, CNC lathes or turning centers feature a turret with multiple cutting tools, all controlled by computer programs. Machines with more tool slots are more complex, versatile, and better suited for intricate designs.

Different lathes and CNC turning centers are optimized for specific operations. Below are common turning techniques:

Straight Turning

Reduces the workpiece diameter uniformly.

Also called rough turning, it often requires additional finishing for precision.

Knurling

Creates crosshatch or diamond patterns on the surface to improve grip.

Used for making bolts, nuts, and threaded holes.

Deep Grooving

Uses a single-point tool to cut deep grooves, removing internal sections.

Taper Turning

Gradually reduces the diameter from one end to the other, producing conical shapes.

Thread Turning

Cuts helical grooves (threads) along the workpiece’s exterior.

Parting (Cut-Off Turning)

Creates narrow grooves or cuts off a section of the workpiece.

CNC turning is compatible with a wide range of materials, including:

Metals: Aluminum, Stainless Steel, Brass, Titanium, Magnesium

Plastics: POM (Delrin), PA (Nylon), PC (Polycarbonate), PMMA (Acrylic), ABS

Each material requires specific machining parameters (e.g., feed rate, cutting speed).

Horizontal CNC Lathe

Most common for industrial applications; suitable for turning and boring.

Vertical CNC Lathe

Holds the workpiece vertically; ideal for heavy or large parts.

Horizontal Turning Center

Enclosed design with milling/drilling capabilities.

Vertical Turning Center

Combines lathe and milling functions; ideal for complex, large workpieces.

CNC Control Panel – Inputs programs and controls operations.

Spindle – Rotates the workpiece.

Headstock – Houses gears, chucks, and control levers.

Tailstock – Supports the workpiece for stability.

Bed – The base structure supporting all components.

Chuck – Grips the workpiece.

Carriage – Guides the cutting tool.

Cutting Tools – Remove material (e.g., turning, threading).

Turret – Holds multiple tools for automated changes.

Foot Pedal – Quickly opens/clamps the chuck.

Facing Tool – Cuts flat surfaces perpendicular to the axis.

Threading Tool – Cuts internal/external threads.

Boring Tool – Enlarges existing holes.

Grooving Tool – Cuts channels (e.g., O-rings).

Knurling Tool – Creates grip-enhancing patterns.

Automotive: Engine blocks, dashboards.

Electronics: Circuit boards, connectors.

Aerospace: Aircraft fasteners, structural components.

CNC turning service is a versatile, high-precision manufacturing technology widely used across industries. Its ability to produce complex parts with tight tolerances makes it indispensable in modern manufacturing.