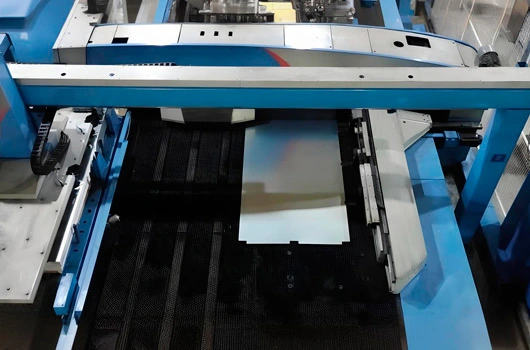

It uses dies to cut out flat parts of a specific shape from a sheet of metal. It's used to make components like small washers and nameplates in home appliances, removing the needed part from the sheet while the rest is scrap.

Specializing in metal stamping for appliance, we pride ourselves on our customization capabilities. Our innovative design team and advanced production equipment enable us to create unique parts that meet your specific requirements, helping you stay ahead in the competitive home appliance market.

It uses dies to cut out flat parts of a specific shape from a sheet of metal. It's used to make components like small washers and nameplates in home appliances, removing the needed part from the sheet while the rest is scrap.

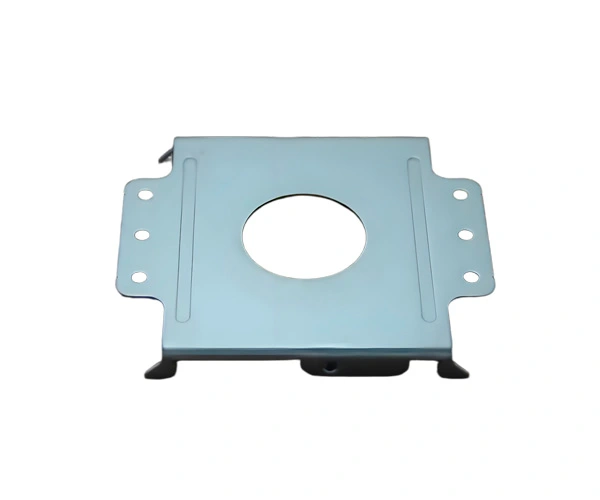

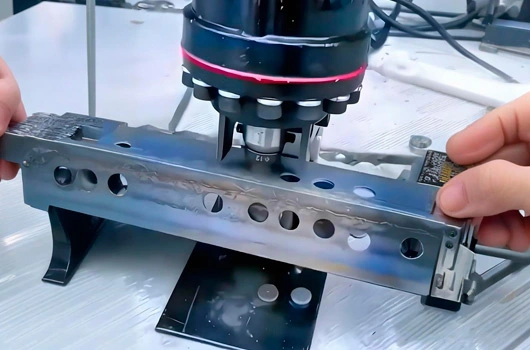

This process creates holes of various shapes and sizes in metal sheets with punching die. In home appliance manufacturing, it's used to make holes for screws, ventilation holes, etc., ensuring the functionality and assembly of parts.

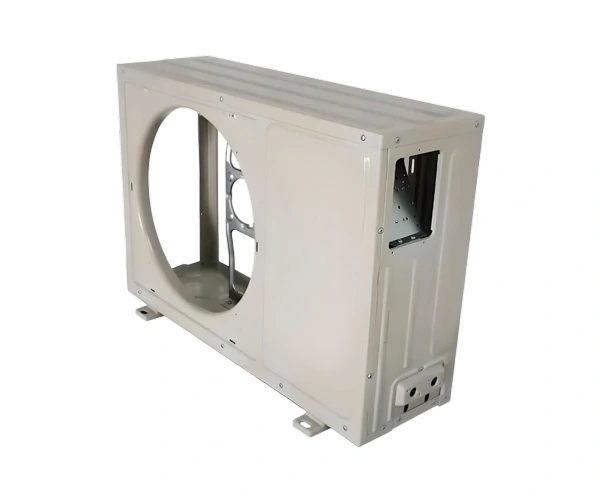

Applying force to bend metal sheets, tubes, or profiles into a certain angle or curvature, bending service is widely used in making brackets, frames, and some shell parts of home appliances, increasing their rigidity and stability.

Transforming flat blanks into hollow parts like cups, boxes, etc. Deep draw stamping is often used to make inner liners of refrigerators, shells of small kitchen appliances, etc. Strict control of process parameters is required to avoid defects like cracking and wrinkling.

Performed on the edges of holes or parts, it can be divided into inward and outward flanging. It improves the strength and rigidity of the edges, and is used for connections or assemblies, such as the edges of some panels and the openings of connecting holes in home appliances.

The metal stamping service is widely used in home appliance components manufacturing for several reasons. It enables high-volume production with high precision, ensuring the consistency and accuracy of components. It's cost-effective as it reduces material waste and labor costs. Moreover, it can enhance the mechanical properties of components, making them more durable. Besides, the process allows for design flexibility to meet various home appliance requirements.