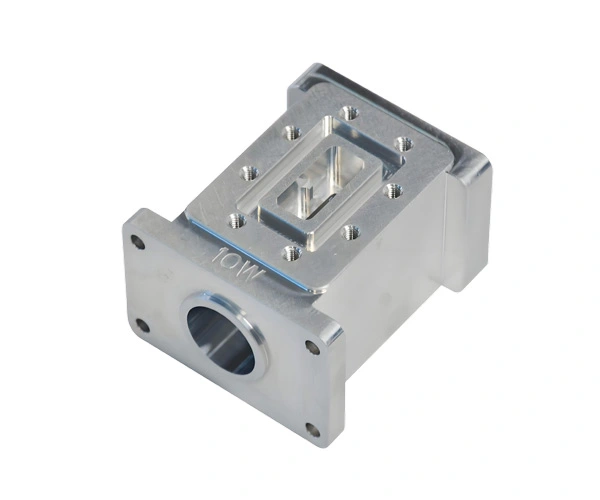

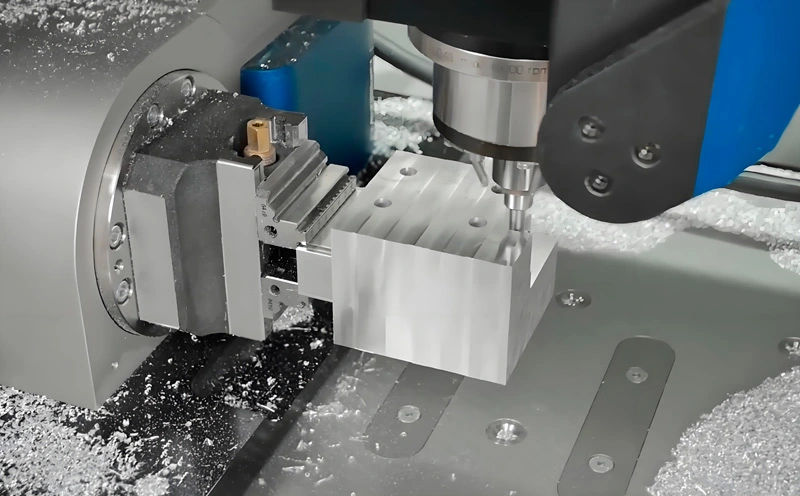

CNC milling precision service is widely used to create various shapes and features on CNC auto parts. It involves removing material with a rotating cutter. This process can produce flat surfaces, grooves, and slots. For example, it's used to shape engine blocks.

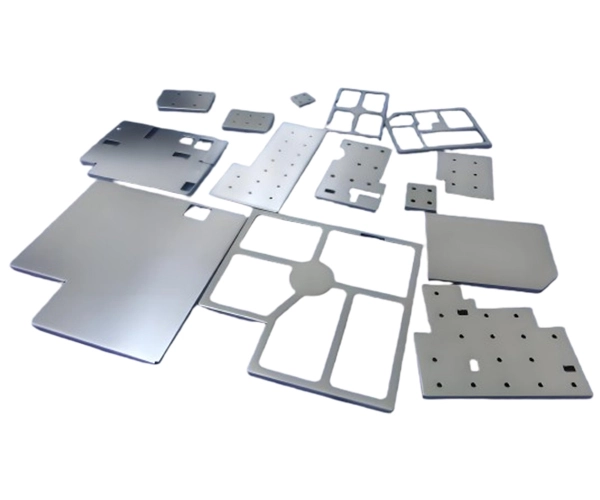

As a CNC car parts manufacturer, we can produce a broad range of automotive components, including engine and transmission brackets, housings, suspension mounts, steering and chassis components, sensor housings, custom metal enclosures, and many more. CNC machining enables complex shapes and tight tolerances, suitable for both structural and functional parts.