The automotive industry is on the cusp of a revolution, and CNC (Computer Numerical Control) machining is at the heart of this transformation. The future of CNC car parts promises enhanced precision, efficiency, and innovation. But what exactly does this future hold? Let's delve into the world of CNC car parts and explore how they are reshaping the automotive landscape.

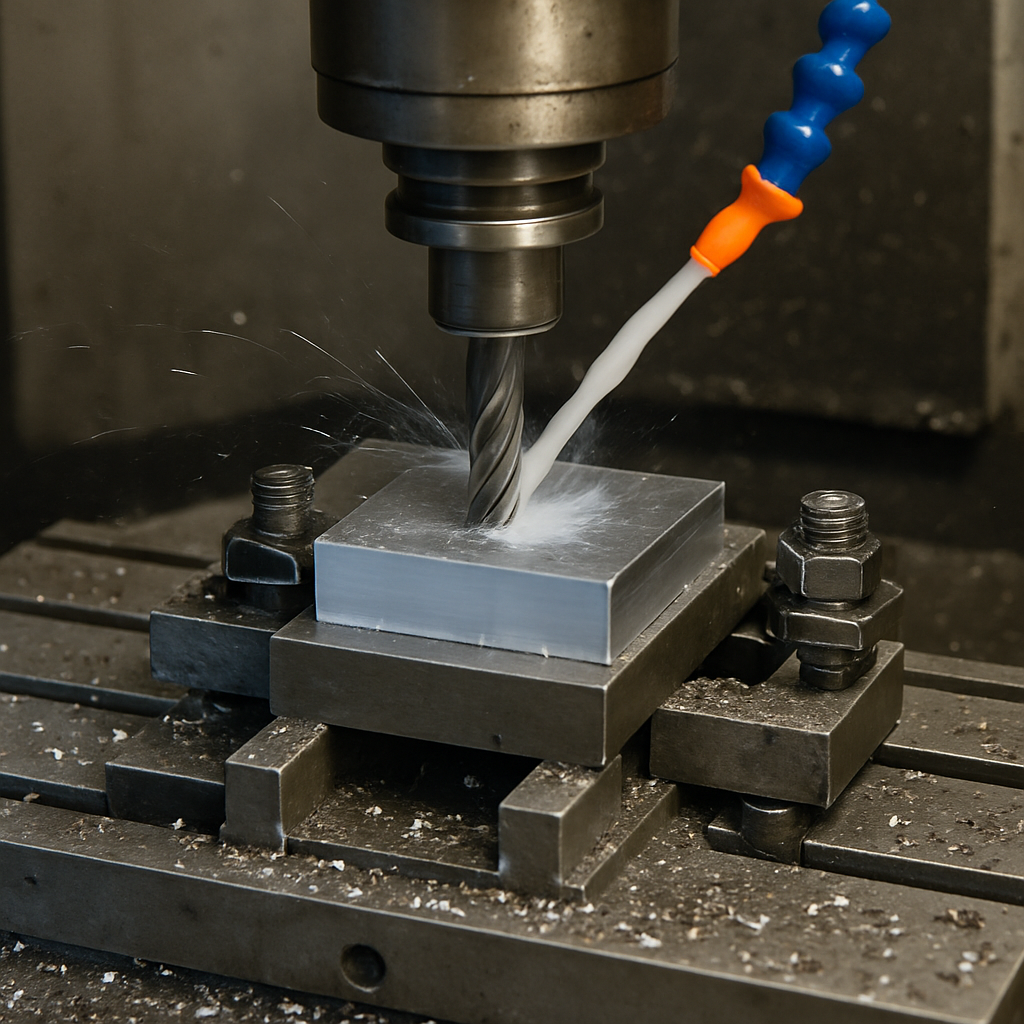

CNC car parts are components manufactured using CNC machining, a process that involves the use of computers to control machine tools. This technology enables the production of precision car parts with unmatched accuracy and consistency.

CNC machining services play a crucial role in the automotive sector by providing manufacturers with the tools they need to produce high-quality car parts. These services encompass a wide range of processes, including milling, turning, and drilling, all of which are controlled by computerized systems to ensure precision.

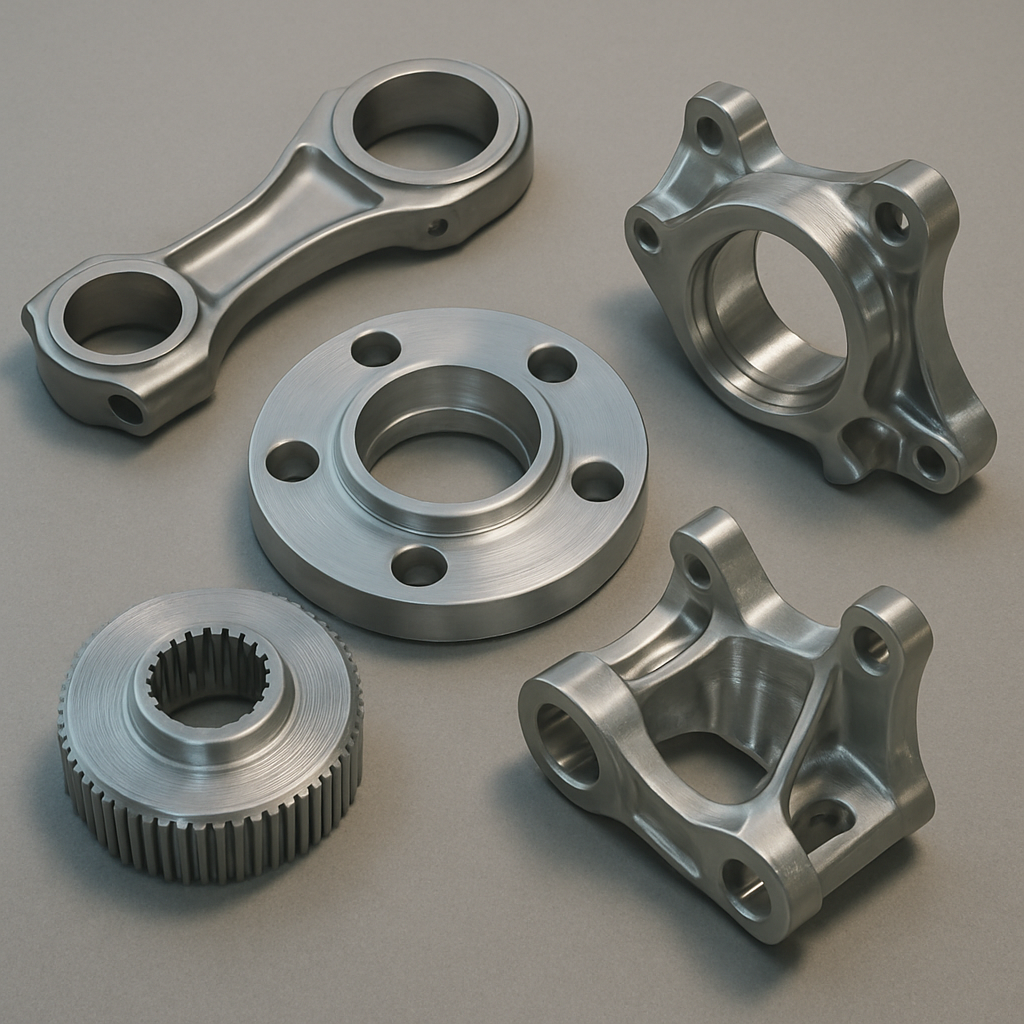

The demand for CNC car parts has led to the emergence of specialized factories dedicated to this technology. These CNC car parts factories are equipped with state-of-the-art machinery and skilled professionals who understand the intricacies of CNC machining.

Precision and Accuracy: CNC machines operate with exceptional precision, ensuring that each car part meets exact specifications. This level of accuracy is crucial for components that play a critical role in vehicle safety and performance.

Efficiency: CNC machining is highly efficient, reducing the time it takes to produce car parts. This efficiency translates to faster production cycles and quicker turnaround times for manufacturers.

Cost-Effectiveness: While the initial investment in CNC technology can be high, the long-term benefits include reduced waste, lower labor costs, and increased production capacity.

The future of CNC car parts is bright, with several innovations on the horizon that promise to reshape the industry.

The use of advanced materials, such as carbon fiber and titanium, is becoming increasingly common in CNC car parts. These materials offer superior strength-to-weight ratios, enhancing vehicle performance and fuel efficiency.

The integration of automation and artificial intelligence (AI) into CNC machining processes is revolutionizing the production of car parts. Automated systems can monitor and adjust machining parameters in real-time, ensuring optimal performance and reducing the likelihood of errors.

CNC machining allows for the customization and personalization of car parts on a scale never before possible. Manufacturers can produce bespoke components tailored to individual customer preferences, offering a level of personalization that sets them apart in the market.

As the automotive industry shifts towards sustainability, CNC car parts are playing a pivotal role in reducing the environmental impact of vehicle manufacturing.

CNC machining is inherently more efficient than traditional manufacturing methods, generating less waste during the production process. This reduction in waste contributes to a smaller carbon footprint for manufacturers.

Modern CNC machines are designed with energy efficiency in mind, consuming less power while maintaining high levels of performance. This focus on energy efficiency aligns with the automotive industry's commitment to sustainability.

While the future of CNC car parts is promising, there are challenges that manufacturers must address to fully realize the potential of this technology.

The demand for skilled professionals who understand CNC machining is growing. Manufacturers must invest in training programs to ensure a steady supply of qualified workers capable of operating and maintaining CNC machinery.

As CNC technology continues to evolve, manufacturers must stay abreast of the latest advancements to remain competitive. This requires ongoing investment in research and development to integrate cutting-edge technologies into their production processes.

The future of CNC car parts is marked by innovation, efficiency, and sustainability. As manufacturers continue to embrace precise CNC machining, the automotive industry is poised for significant advancements in the production of precision car parts. With the right investments in technology and workforce development, CNC car parts factories can lead the way in reshaping the automotive landscape for years to come.

CNC machining services are not just transforming car parts manufacturing; they are setting the stage for a new era of automotive excellence. As we look to the future, it is clear that CNC technology will play a central role in driving the industry forward.