ZJJG Technology Co., Ltd., a leading high-tech enterprise in China's equipment manufacturing sector, specializes in smart equipment for new energy, photovoltaic, and precision machinery applications. Boasting a global footprint, it maintains stringent quality standards for core components to ensure the reliability of end equipment.

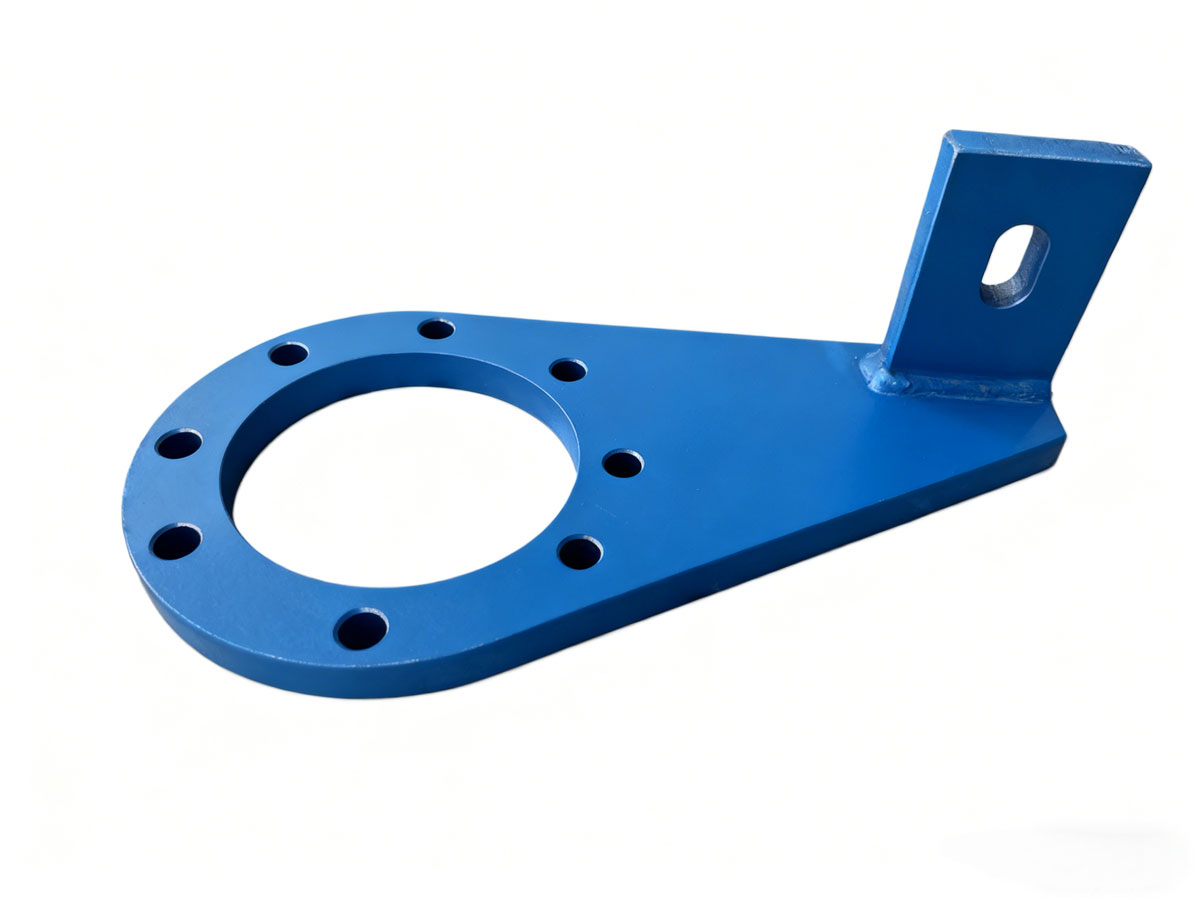

During the upgrade of its new energy smart equipment production line, ZJJG Technology sought a reliable partner for custom processing of the Motor Torque Arm—a critical transmission component. Our proven expertise in precision component machining and rigorous quality control system secured us the collaboration following multiple rounds of evaluation.

As a key transmission part, the Motor Torque Arm required high standards for flatness, welding stability, dimensional accuracy, and surface treatment, presenting several core challenges.

Strict steel plate flatness was essential to ensure assembly precision and torque transmission efficiency, which placed high demands on base material selection and pre-processing.

Secure welding and thorough post-weld slag removal were imperative to guarantee service life, preventing defects such as incomplete welding and slag inclusion.

Compliance with the GB/T1804-m tolerance standard was mandatory, as minor dimensional deviations could result in assembly failure, requiring precise control over machining and testing processes.

Sharp edges required deburring, and non-machined surfaces needed uniform, durable painting—both critical for assembly safety and corrosion resistance in real-world operating environments.

To address these requirements, we tailored a full-process precision solution integrating premium material selection, professional machining techniques, and strict quality oversight.

We utilized national standard carbon structural steel plates, conducting rigorous pre-processing flatness testing to eliminate substandard materials. For welding, pre-weld CNC milling ensured neat joint surfaces, gas tungsten arc welding (GTAW) guaranteed stable quality, and post-weld slag removal delivered secure, clean welds.

High-precision CNC machining centers (with ±0.01mm positioning accuracy) handled overall processing, while three-coordinate measuring machines performed comprehensive dimensional inspections to ensure full compliance with GB/T1804-m standards.

Surface treatment involved a combination of mechanical and manual deburring for smooth edges. Non-machined surfaces underwent a three-layer painting process (derusting & phosphating → anti-rust primer → corrosion-resistant topcoat) in a dust-free spray booth, ensuring a uniform and durable finish.

A dedicated quality control team provided real-time process tracking and issued detailed inspection reports (covering material qualifications, dimensional precision, and welding quality), ensuring complete quality transparency for ZJJG Technology.

Full-Process Quality Tracking: Dedicated QC team for real-time monitoring; detailed quality inspection reports (material, precision, welding) provided for transparency.

After the successful delivery and on-site installation of the custom Motor Torque Arm, ZJJG Technology conducted a comprehensive evaluation of the product quality and our service level, and gave a high recognition and positive feedback. A senior purchasing manager of ZJJG Technology, who is in charge of the cooperation project, said: "As a key transmission component of our new energy smart equipment, the Motor Torque Arm has extremely strict requirements on processing precision and structural stability. From the initial technical communication to the final product delivery, the team has shown professional professionalism and rigorous work style."

He further commented on the product quality: "The delivered Motor Torque Arm perfectly meets all our technical requirements. The steel plate is flat without any deformation, the welding is firm and the weld seam is clean without slag residue. The dimensional tolerance has been strictly controlled in accordance with the GB/T1804-m standard, and the assembly with other components is smooth and precise. In addition, the edge deburring is thorough, the surface painting is uniform and smooth, and the anti-corrosion performance has passed our preliminary testing. After being put into the production line for trial operation, the product has been running stably and reliably, which effectively guarantees the normal operation efficiency of our terminal equipment and lays a solid foundation for the smooth upgrade of our production line."

"What impresses us most is the full-process quality tracking service provided by the team. They issued detailed quality inspection reports in a timely manner at each key processing stage, including material inspection certificates, flatness test data, welding quality detection reports and dimensional precision test records. This transparent and standardized quality management system makes us fully assured of the product quality. We are very satisfied with this cooperation and have included the team in our list of core cooperative suppliers. We look forward to in-depth cooperation with them in more precision component processing projects such as new energy equipment accessories in the future, and jointly promote the technological upgrading and development of the industry."