In modern manufacturing, progressive die stamping is a widely used metal forming process primarily employed for the production of high-volume, high-precision metal parts. Particularly in industries such as automotive, home appliances, and electronics, progressive die stamping plays a crucial role. It achieves efficient and precise production by gradually forming metal sheets step by step through the design of progressive dies.

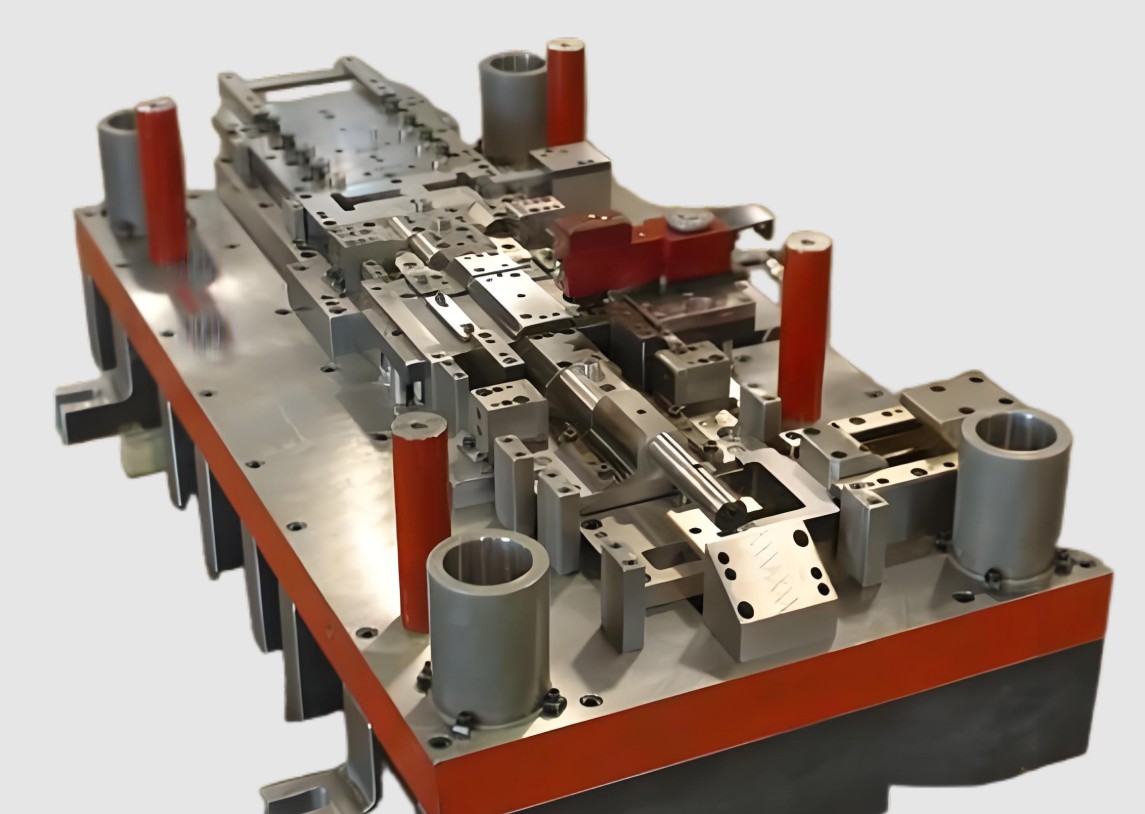

The design of progressive dies is the core of this technology—key to achieving efficient production. A good progressive die design not only affects production efficiency but also has significant impacts on the quality of finished products, the lifespan of the dies, and production costs.

Progressive die stamping is a metal forming process that involves placing metal sheets into the die and progressively completing operations such as blanking, drawing, bending, and forming to manufacture parts with complex shapes.

Progressive die stamping design refers to designing die structures that meet production requirements, optimize production efficiency, and reduce production costs for the progressive die stamping process. A good design enables dies to have longer service life and higher production stability.

The relationship: Progressive die stamping design is the foundation and prerequisite of the progressive die stamping process. The two are closely linked, and the quality of the design directly influences the efficiency and quality of the stamping process. An optimized progressive die stamping design enhances the functionality of the dies, making the stamping process smoother and more efficient.

Progressive die stamping typically employs a series of operations to progressively process metal sheets into the desired parts through the multi-stage structure of the die. The basic process includes:

Feeding: Metal sheets are fed into the die through the feeding system.

Step-by-step stamping: In multiple die cavities, the metal sheets are sequentially blanked, drawn, bent, etc. Each stage of stamping gradually perfects the shape of the part.

Part removal: After completing all stamping operations, the parts are removed through the stripping system.

This progressive stamping method allows precise control of each operation and enables multiple processing steps to be completed on a single die, significantly improving production efficiency.

In the progressive die stamping process, the design of the dies is crucial. An efficient progressive die design should have the following characteristics:

Reasonable process layout

A good die design requires scientific planning of the process, reasonably setting each stamping step to ensure coordination between each operation. Each stamping step should seamlessly connect to avoid interference and deviations during production.

Optimized die structure

The structure of progressive dies should be designed according to the shape of the product and the characteristics of the material. High-precision dies can ensure accurate dimensions of the finished product, reduce waste, and improve material utilization.

Extended die life

Die design needs to consider durability, and the selection of materials and heat treatment processes is crucial. A reasonable design can extend die life and reduce maintenance costs.

Cost control

Progressive die design should focus on cost control. By optimizing the design to reduce unnecessary complexity and material waste, production costs can be effectively lowered.