In CNC turning, nothing destroys surface finish, tool life, or dimensional accuracy faster than chatter, tool deflection, and tolerance drift. These issues become especially challenging when machining long, slender, thin-walled, or high-precision components—exactly the types of projects where manufacturing consistency matters most.

At MAXTECH CNC, where our specialty is tight-tolerance precision CNC turning services for high-complexity parts, controlling these instability factors is a daily priority. In this guide, we break down the real causes of turning-related vibration and dimensional inaccuracy and share practical machining strategies that help ensure repeatable, production-grade quality.

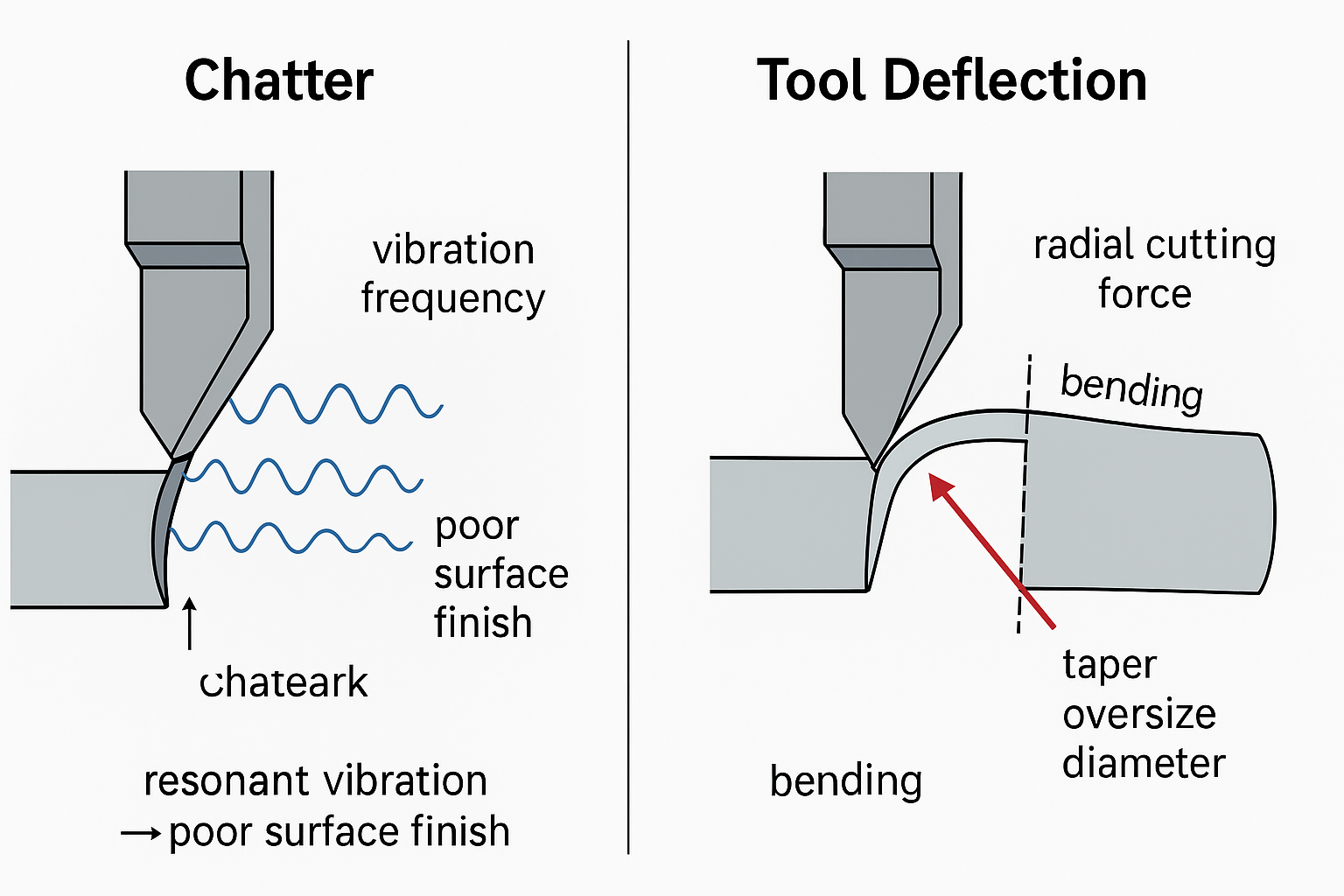

Chatter and deflection are often grouped together, but they originate from different mechanical sources—and require different corrective actions.

Chatter occurs when the cutting tool, workholding, or workpiece vibrates at a harmonic frequency.

Common causes include:

Insufficient rigidity in the setup

Excessive stick-out of bar stock or boring bars

Incorrect cutting parameters (RPM, feed, depth of cut)

Dull or inappropriate inserts

Tool engagement forces exceeding structural stiffness

Tool deflection is the bending or flexing of the tool or workpiece during cutting.

This typically occurs with:

Long, slender “noodle” parts

Deep internal bores

Thin-walled components

High cutting loads causing systematic deviation

Deflection rarely shows up as chatter—it shows up as tolerance drift, undersized bores, taper, or inconsistent diameters.

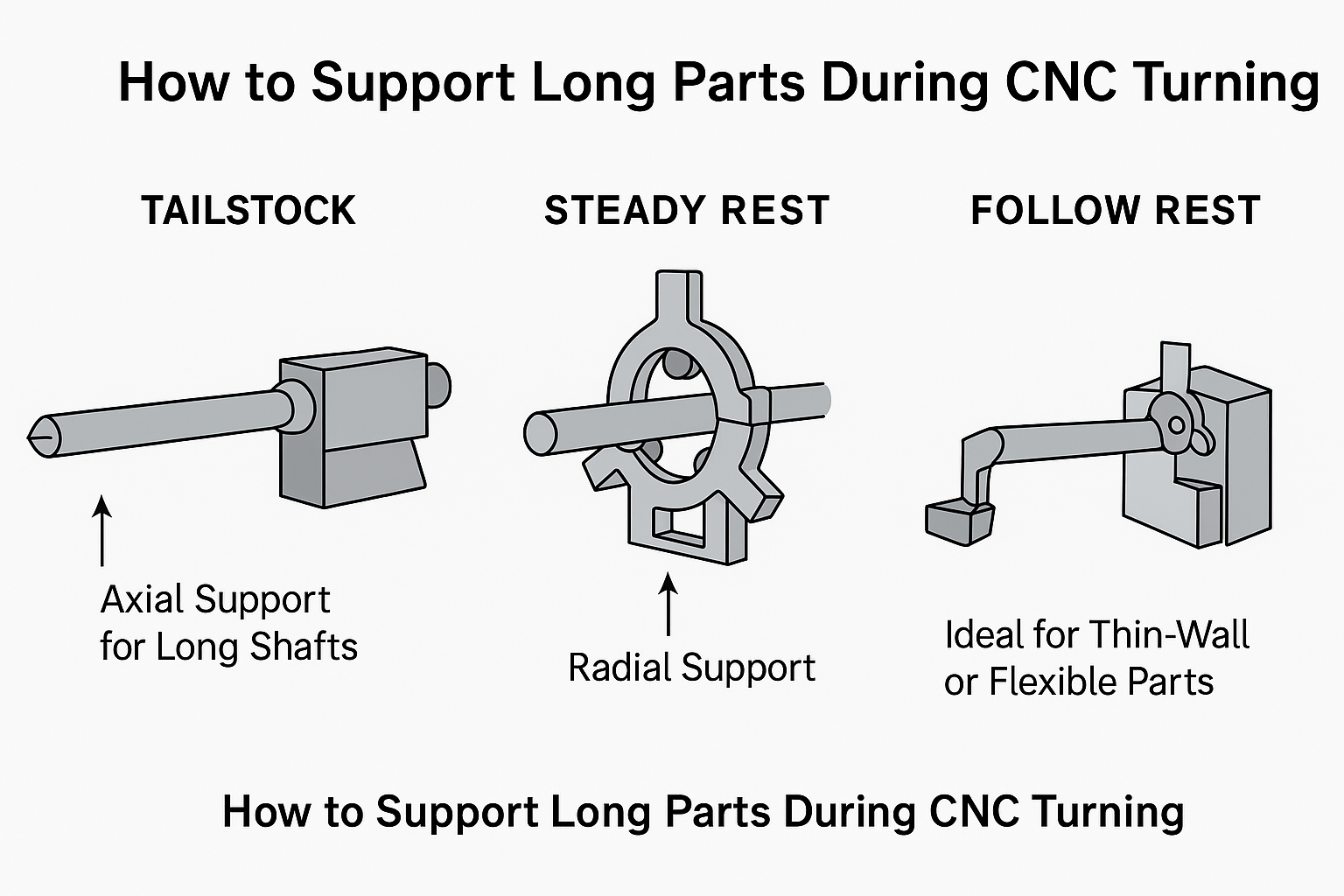

For demanding long-part machining, support systems are mandatory.

Tailstock: Best for axial support during turning

Steady rest: Prevents radial movement on long shafts

Follow rest: Travels with the carriage for thin flexible components

A part that deflects even 0.05 mm can lead to oversized diameters or unpredictable tapers. MAXTECH CNC frequently uses multi-support setups on aerospace shafts, instrumentation parts, and precision pins to guarantee straightness and dimensional stability.

The rule of thumb

Tool overhang should be no more than 1.5× the bar diameter.

For boring bars, exceeding 5× can drastically increase deflection.

Best practices:

Use the largest diameter boring bar that fits the bore

Use carbide or damped boring bars for deep holes

Switch to anti-vibration bars if stick-out > 8×D

To minimize bending forces:

Lower depth of cut (DOC)

Increase feed slightly

Use sharper inserts

Reduce tool nose radius

A smaller nose radius reduces radial cutting force, directly lowering the risk of deflection.

Every machine-tool-workpiece combination has certain spindle speeds that excite vibration.

If chatter occurs:

Decrease spindle speed by 10–20%

Or increase speed to skip the resonant frequency zone

This simple adjustment instantly eliminates chatter in many cases.

Insert choice affects stability more than most operators realize.

Stable for chatter-prone workpieces:

Positive rake

Sharp cutting edges

Small nose radius

High-polish chipbreakers

Less stable but stronger:

Negative rake

Heavy nose radius

Thick inserts

At MAXTECH CNC, we regularly choose optimized insert geometries when machining aerospace aluminum, stainless steels, and precision brass components to maintain surface finish and dimensional repeatability.

Chatter thrives in flexible systems.

Improve rigidity by:

Using shorter toolholders

Using thicker, stiffer boring bars

Ensuring proper chuck pressure

Switching to soft jaws or custom jaws

Using collet-style chucks for small diameters

Even a small increase in setup rigidity can dramatically reduce vibration amplitude.

Tolerance inconsistency often comes from internal stresses and heat—not only from chatter.

General rule:

Rough first, allow stress to relieve, then finish

For precision internal bores: finish in the same setup

For long parts: finish with full support (tailstock/steady rest)

If roughing removes a large amount of material, the part can subtly move as stress is released. This is why aerospace components are often rough-machined, stress-relieved, then finish-machined.

When used properly (G96), CSS improves:

Consistent cutting load

Better chip control

More even tool wear

But excessive CSS at small diameters generates heat—leading to tolerance growth.

Thermal growth affects:

The tool

The spindle

The part itself

In production environments, tolerance drift usually becomes noticeable once the spindle has been running for a period of time.

Professional strategies used in precision machining:

Pre-warm spindle cycles

Controlled coolant temperature

Avoiding long dry-running periods

Taking measurement at consistent temperature intervals

MAXTECH CNC uses climate-stable machining cells to ensure repeatability for medical, robotic, and defense components where tolerances often fall within ±0.005 mm.

Threading is one of the most sensitive turning operations due to high radial load and multiple passes.

Incorrect insert geometry magnifies forces and increases chatter risk.

Essential steps:

Set tool perpendicular to thread axis

Touch off flank using magnification or optical probes

Use G76 or G32 with slight radial offset

Adjust tool wear comp (G41/G42) if the thread is undersized/oversized

Picking up threads is a common service at MTCNC for repair parts, custom adapters, and re-machining operations.

Here is a practical summary that machinists and engineers use daily:

Lower/increase RPM to escape resonance

Increase rigidity at every node

Use sharper inserts

Shorten tool overhang

Use proper workholding

Use tailstock, steady rest, or follow rest

Reduce DOC, increase feed

Use anti-vibration bars

Increase part support

Separate roughing and finishing

Allow time for stress relief

Control heat

Maintain consistent measurement routines

Chatter, deflection, and tolerance drift are unavoidable challenges in CNC turning—but with the right strategy and setup, they can be controlled to achieve highly consistent, repeatable precision.

At MAXTECH CNC, these techniques form the foundation of our workflow for manufacturing tight-tolerance, complex CNC turned components for industries where precision matters most—medical, aerospace, robotics, instrumentation, automotive, and more.

If you need reliable, high-accuracy CNC turning for prototype or production parts, our team can help ensure your components meet the highest standards of dimensional stability and surface quality.