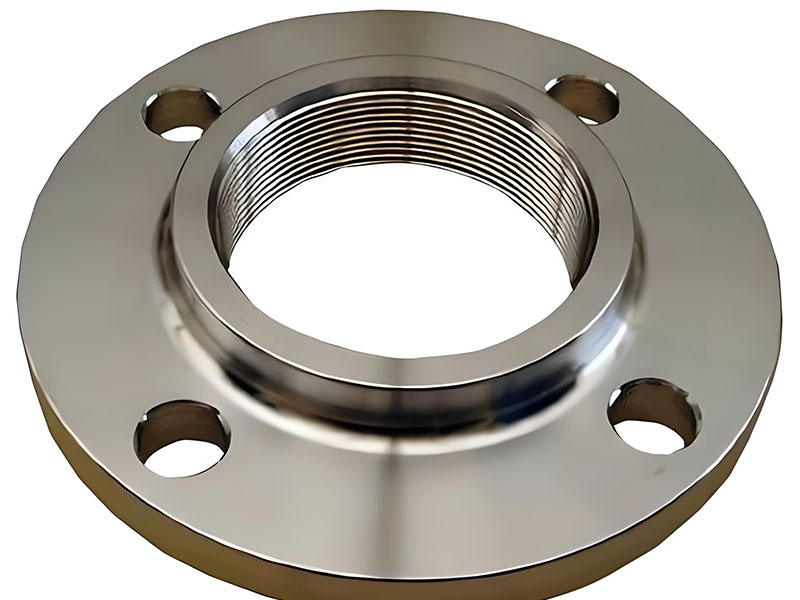

MAXTECH is a trusted leader in designing and manufacturing high-quality automotive components, specializing in precision-engineered parts for global automakers. Our latest collaboration with JGJM Automotive—an innovator in passenger, commercial, and electric vehicles—delivers custom automotive flanges across eight critical applications: drive shaft flanges, intake manifold flanges, exhaust manifold flanges, exhaust tailpipe flanges, water pump flanges, fuel line flanges, catalytic converter flanges, and oil pump flanges. As core connection components, flanges ensure leak-proof sealing, structural alignment, and durability across powertrain, fluid, and exhaust systems; leveraging our decades of automotive manufacturing expertise and advanced production capabilities, we overcame application-specific technical challenges to support JGJM Automotive’s full vehicle platform launch.

Automotive flanges span diverse operating environments—from high-temperature exhaust systems (up to 800°C) to high-pressure fluid lines (up to 15 bar)—and require tailored performance for each application. The project with JGJM Automotive presented cross-cutting and application-specific hurdles:

Application-Specific Material Demands: Exhaust-related flanges (manifold, tailpipe, catalytic converter) needed extreme heat resistance (800°C+), while fluid system flanges (water pump, fuel line, oil pump) required corrosion resistance and compatibility with coolants, fuels, and oils. Drive shaft flanges demanded high torque-bearing strength (up to 500 N·m), and intake manifold flanges required airtight sealing to prevent pressure loss.

Ultra-Tight Sealing & Alignment Tolerances: All flanges needed tolerances of ±0.02mm for bolt holes and mating surfaces to ensure leak-proof connections—misalignment or dimensional deviation would cause fluid leakage (fuels/coolants), exhaust gas escape, or powertrain inefficiency.

Complex Load & Environmental Resistance: Exhaust flanges endured thermal cycling (-40°C to 800°C) and vibration; fluid system flanges faced pressure spikes and chemical corrosion; drive shaft flanges bore continuous torque and mechanical stress. All required 200,000+ km durability without deformation or failure.

High-Volume & Rapid Prototyping Dual Needs: JGJM Automotive required 30 prototypes per flange type (240 total) for performance testing within 15 days, followed by 5,00 units per type (40,00 total) in low-volume production within 5 weeks to align with their multi-model launch timeline.

Consistent Quality Across Variants: With eight distinct flange types (varying in size, geometry, and function), maintaining uniform quality control and production efficiency was critical to avoiding delays or cost overruns.

We tailored a modular yet specialized manufacturing approach to address the unique needs of each flange type, combining advanced technologies, application-specific materials, and strict quality control.

① CNC Machining (Primary Production Technology for Metal Flanges)

Application: Used for all metal flanges (drive shaft, intake/exhaust manifold, catalytic converter, water pump, oil pump) to achieve precision geometry and tight tolerances. We deployed:

CNC milling centers for complex mating surfaces (e.g., exhaust manifold flanges with curved sealing edges) and CNC turning for cylindrical flanges (e.g., drive shaft flanges).

High-precision spindles (20,000 RPM) and on-machine laser probing to validate ±0.02mm tolerance for bolt holes and mating surfaces, ensuring leak-proof sealing.

Process Optimization: Custom toolpaths for each flange type—e.g., deep-hole drilling for fluid line flanges (ensuring internal smoothness for unobstructed flow) and reinforced edge machining for drive shaft flanges (enhancing torque resistance).

② Sheet Metal Fabrication (Secondary Structural Flanges)

Application: Used for lightweight exhaust tailpipe flanges and intake manifold flanges. Processes included laser cutting (±0.03mm edge precision) for flat blanks and CNC bending for forming mounting flanges, ensuring structural rigidity while reducing weight by 10% compared to solid machining.

③ 3D Printing (Rapid Prototyping)

Technology: Selected SLM (Selective Laser Melting) for metal prototypes (exhaust, drive shaft flanges) and SLS (Selective Laser Sintering) for plastic-reinforced flanges (intake manifold, fluid line). SLM enabled fast production of heat-resistant metal prototypes (5-day lead time), while SLS validated plastic-to-metal integration (3-day lead time).

Lead Time: Delivered 240 total prototypes across 8 flange types in 8 days (2 days ahead of C Automotive’s requirement), enabling parallel performance testing for all variants.

④ Custom Surface Finishing (Application-Specific Treatments)

Tailored finishes to enhance durability, corrosion resistance, and heat tolerance for each flange type:

Finish Type | Applicable Flange Types | Key Benefits | Thickness |

High-Temperature Powder Coating | Exhaust Manifold/Tailpipe/Catalytic Converter | Resists 850°C+ heat; prevents rust from exhaust gases | 0.1–0.15mm |

Anodization | Water Pump/Fuel Line/Oil Pump | Enhances corrosion resistance; compatible with coolants/fuels | 0.01–0.03mm |

Nickel Plating | Drive Shaft | Boosts surface hardness; improves torque transmission durability | 0.005–0.01mm |

Chromate Conversion Coating | Intake Manifold | Prevents corrosion; improves adhesion for gaskets (airtight sealing) | 0.25–1μm |

E-Coating | General Metal Flanges | Uniform anti-rust protection; adheres to complex geometries | 0.02–0.035mm |

Every material was matched to the flange’s operating environment and load requirements:

Material | Applicable Flange Types | Key Benefits | Technology Compatibility |

Heat-Resistant Steel (42CrMo4) | Exhaust Manifold/Catalytic Converter | Withstands 800°C+; high tensile strength (1,000 MPa) | CNC Machining, High-Temp Powder Coating |

Aluminum Alloy (6061-T6) | Water Pump/Fuel Line/Oil Pump | Lightweight; corrosion-resistant; compatible with fluids | CNC Machining, Anodization |

Titanium Alloy (Ti-6Al-4V) | Drive Shaft | High torque resistance; lightweight (40% lighter than steel) | CNC Machining, Nickel Plating |

High-Strength Steel (A36) | Exhaust Tailpipe/Intake Manifold | Cost-effective; structural rigidity; durable for medium temperatures | Sheet Metal Fabrication, E-Coating |

PA (Nylon) + Glass Fiber | Intake Manifold (Reinforced) | Dimensional stability; airtight sealing; compatible with metal components | SLS 3D Printing, Injection Molding |

ISO Compliance: All processes comply with quality standards, with full traceability for material sourcing and production parameters across all 8 flange types.

Application-Specific Testing:

Exhaust flanges: Thermal cycle testing (-40°C to 800°C for 1,000 cycles) and leak testing (10 bar pressure).

Fluid system flanges: Pressure spike testing (20 bar) and chemical compatibility testing with automotive fuels/coolants.

Drive shaft flanges: Torque testing (550 N·m) and fatigue cycle testing (100,000 cycles).

Dimensional Validation: Each production unit is inspected by fully automatic image measuring instruments and other measuring machines to verify alignment and tolerances, ensuring perfect fit with TNS Automotive's transmission system components.

"MAXTECH can provide different types of automotive flanges—each tailored to its unique operating environment—was instrumental in our multi-model platform launch. The flanges not only met our strict tolerance and durability requirements but also exceeded our expectations for application-specific performance: exhaust flanges showed zero deformation after 1,000 thermal cycles, fluid system flanges maintained leak-proof sealing under pressure spikes, and drive shaft flanges handled 550 N·m torque without wear.

What stood out most was their modular manufacturing approach: they balanced specialized materials (like heat-resistant steel for exhaust flanges and titanium for drive shafts) with consistent quality control, ensuring every variant performed reliably. Their rapid prototyping service (8-day delivery for 240 prototypes!) kept our parallel testing on track, and their team’s expertise in optimizing CNC toolpaths for each flange type eliminated production bottlenecks.

We trust MAXTECH’s commitment to precision and application-specific engineering, and we’re excited to expand our partnership for future powertrain and fluid system components.”

— Director of Component Engineering, JGJM Automotive

ISO Certified: Rigorous quality control for safety-critical and performance-critical flanges.

Application-Specific Expertise: Specialized solutions for 8+ flange types, tailored to heat, pressure, torque, and corrosion requirements.

Comprehensive Capabilities: CNC Machining, Sheet Metal Fabrication, 3D Printing, and custom finishing—all optimized for flange production.

High-Volume & Rapid Prototyping: Prototypes in 3–8 days; low-volume production in 3–5 weeks, even for multi-variant orders.

Material Mastery: Deep expertise in automotive-grade metals and plastics, matched to operating environments.

24/7 Engineering Support: Fast quotation (within 24 hours) and real-time project updates for complex orders.

Get in Touch

Ready to elevate your vehicle’s powertrain and fluid systems with precision machined flange? Contact MAXTECH today for a custom solution.