The sheet metal is punched into the required outer contour through stamping dies. For example, the preliminary shape cutting of automotive body panels lays the foundation for subsequent processing.

Our Stamping Automotive Parts are engineered with precision. Employing advanced stamping techniques, we create parts with high strength and durability. These parts are crucial for various automotive systems, ensuring optimal vehicle performance and safety. Whether for engine components or body structures, our products meet the rigorous demands of the automotive industry.

The sheet metal is punched into the required outer contour through stamping dies. For example, the preliminary shape cutting of automotive body panels lays the foundation for subsequent processing.

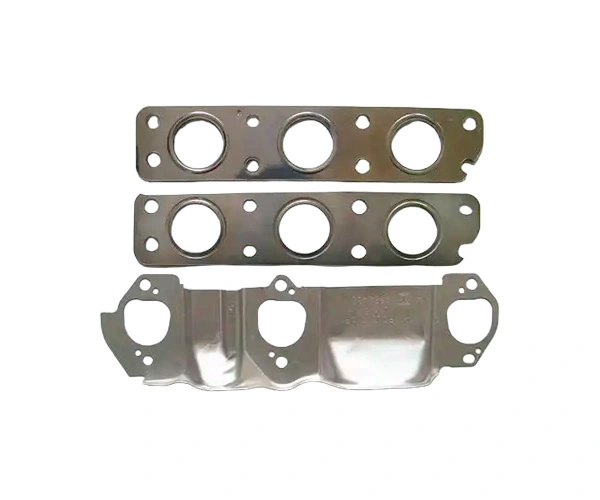

Holes of various shapes are punched in the formed parts for installing bolts, rivets, etc. Many of the mounting holes on automotive engine blocks are completed by the piercing process.

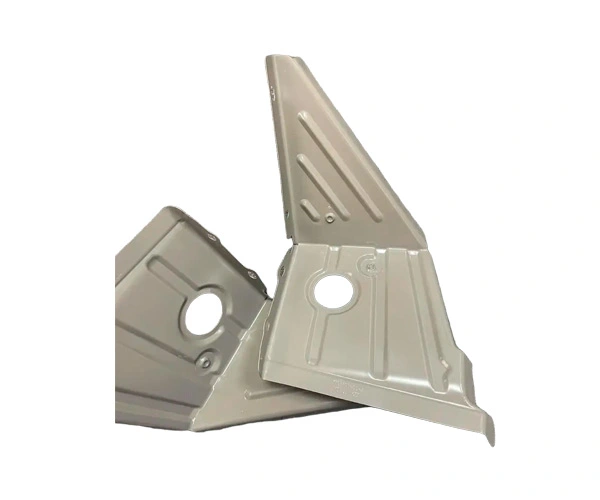

The flat-shaped metal material is bent into a certain angle or shape as required by the design. The door frames of automobiles often take on unique curvatures through this metal bending process.

The flat blank is stamped into an open-ended hollow shape. The automotive fuel tank is transformed from a flat metal sheet into a complex container shape through the drawing process.

Efficient production

The metal stamping process can produce a large number of parts of the same specifications in a short period of time. High speed stamping machines can complete multiple stamping operations per minute, greatly improving production efficiency and meeting the large-scale production needs of the automotive industry.

Cost advantage

Once the stamping mold is completed, the cost of producing individual parts in the future is extremely low. And the material utilization rate is high, reducing waste and lowering overall production costs.

Reliable quality

Stamping technology can ensure the dimensional accuracy and consistency of parts. Precision molding of molds ensures stable quality of automotive components, meets strict industry standards, and guarantees automotive safety performance.