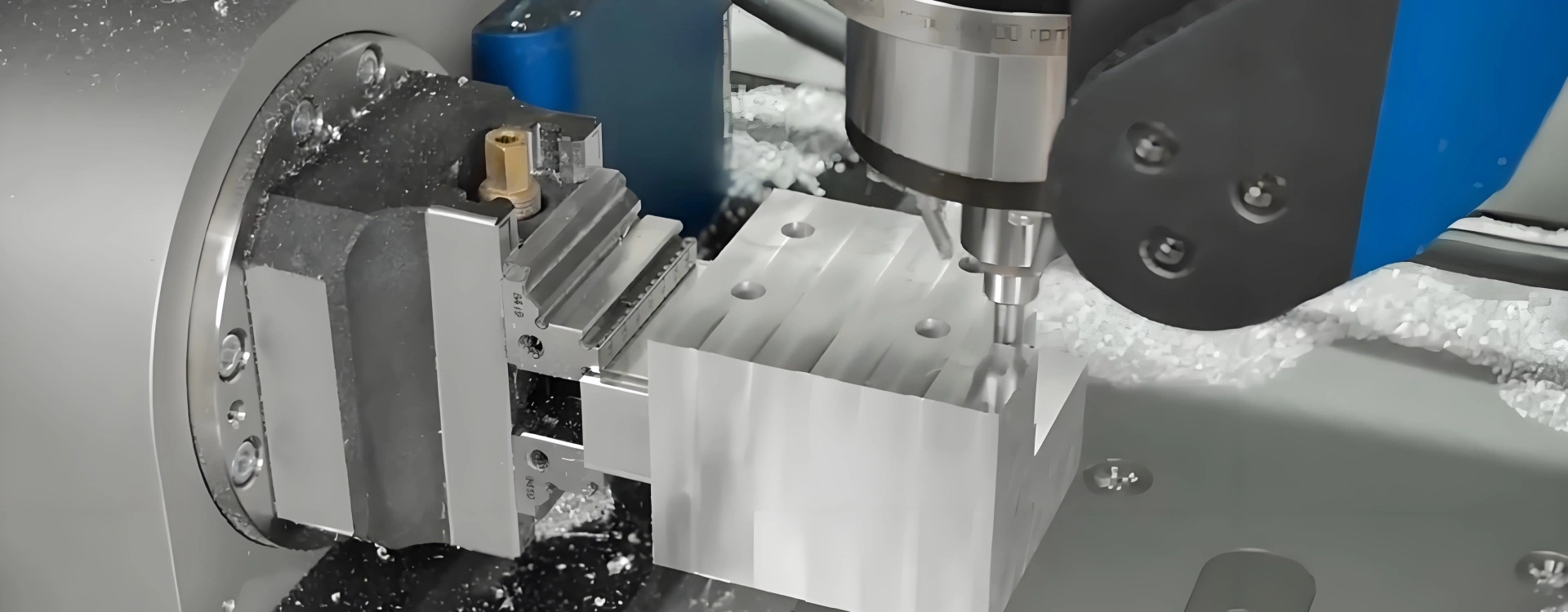

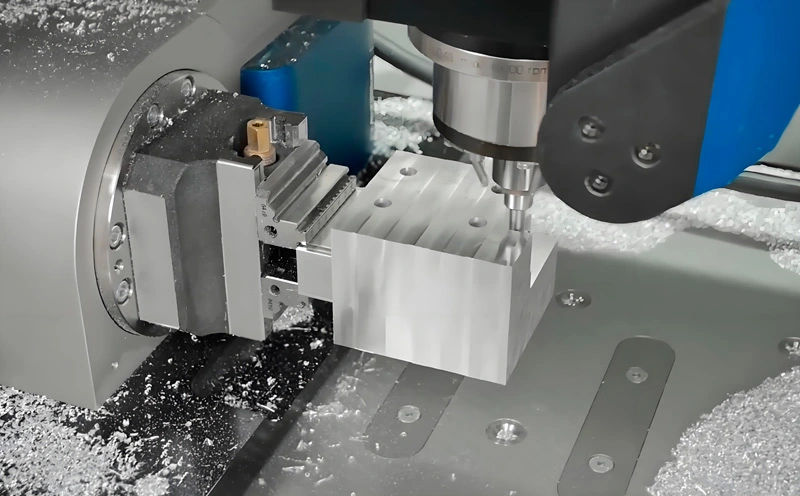

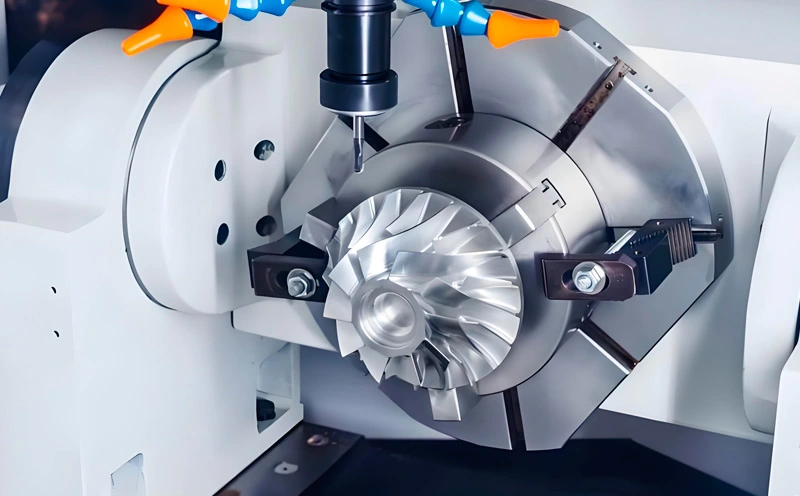

Our CNC drilling services guarantee exceptional precision. Advanced machinery and calibrated tools ensure holes are drilled to exact specifications, with tolerances as tight as ±0.005mm. This level of accuracy is crucial for industries like electronics and aerospace, where even the slightest deviation can impact performance.

Used for manufacturing engine cylinder blocks, braking systems, transmissions, and other components, ensuring precise hole positions and sizes to enhance automotive performance and safety.