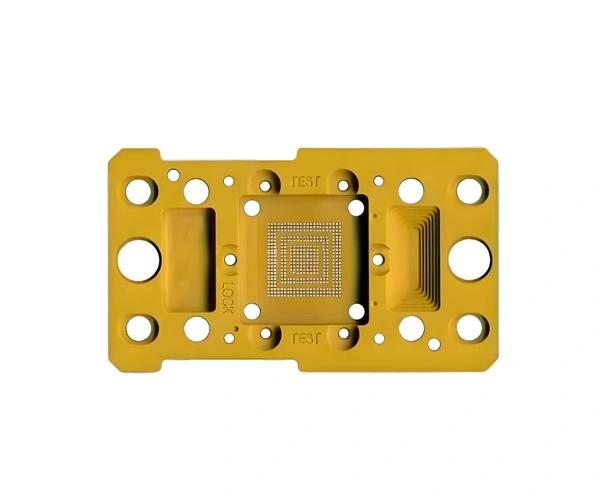

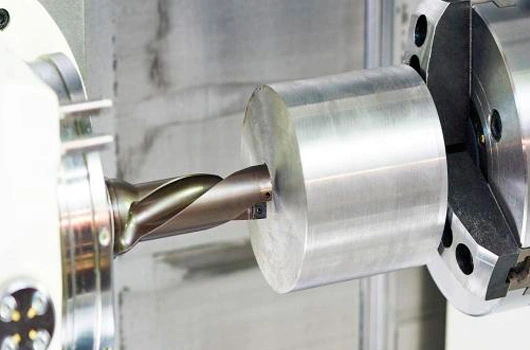

Milling is widely used to shape CNC electronics parts. With high-speed cutters, precision milling services can create precise slots, grooves, and complex geometries. This process is vital for fabricating PCB boards and enclosures.

At MAXTECH, we are a leading provider of CNC electronics parts. Our production process combines cutting-edge CNC technology with the expertise of our technicians. We focus on precision and quality, using high-grade materials to manufacture components that meet the exacting standards of the electronics industry. From heat sinks to connectors, our CNC electronics parts play a vital role in the seamless operation of various electronic devices, ensuring optimal performance and reliability.

Milling is widely used to shape CNC electronics parts. With high-speed cutters, precision milling services can create precise slots, grooves, and complex geometries. This process is vital for fabricating PCB boards and enclosures.

Drilling is essential for creating holes in electronics parts for component mounting and wiring. CNC drilling ensures accurate hole placement and size. It's used in circuit boards and chassis fabrication.

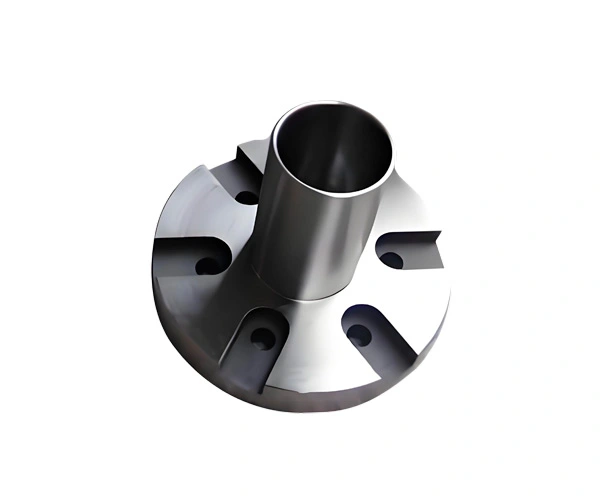

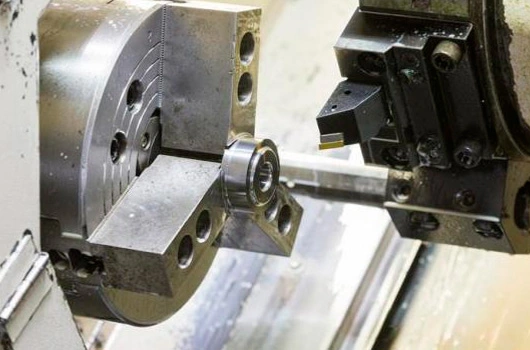

CNC turning service is employed to produce cylindrical electronics components like shafts and pins. The CNC lathe rotates the workpiece while a tool shapes it to the required diameter and finish. This process guarantees dimensional accuracy.

We offer a variety of materials for CNC electronics parts. Aluminum is popular for its excellent heat dissipation and lightweight properties, while copper is favored for its outstanding electrical conductivity. For surface treatment, anodizing aluminum parts provides enhanced corrosion resistance and insulation. Nickel plating on copper components improves solderability and wear resistance. Additionally, conformal coating can be applied to protect against moisture and contaminants, ensuring the longevity and reliability of our CNC electronics parts in diverse operating conditions.