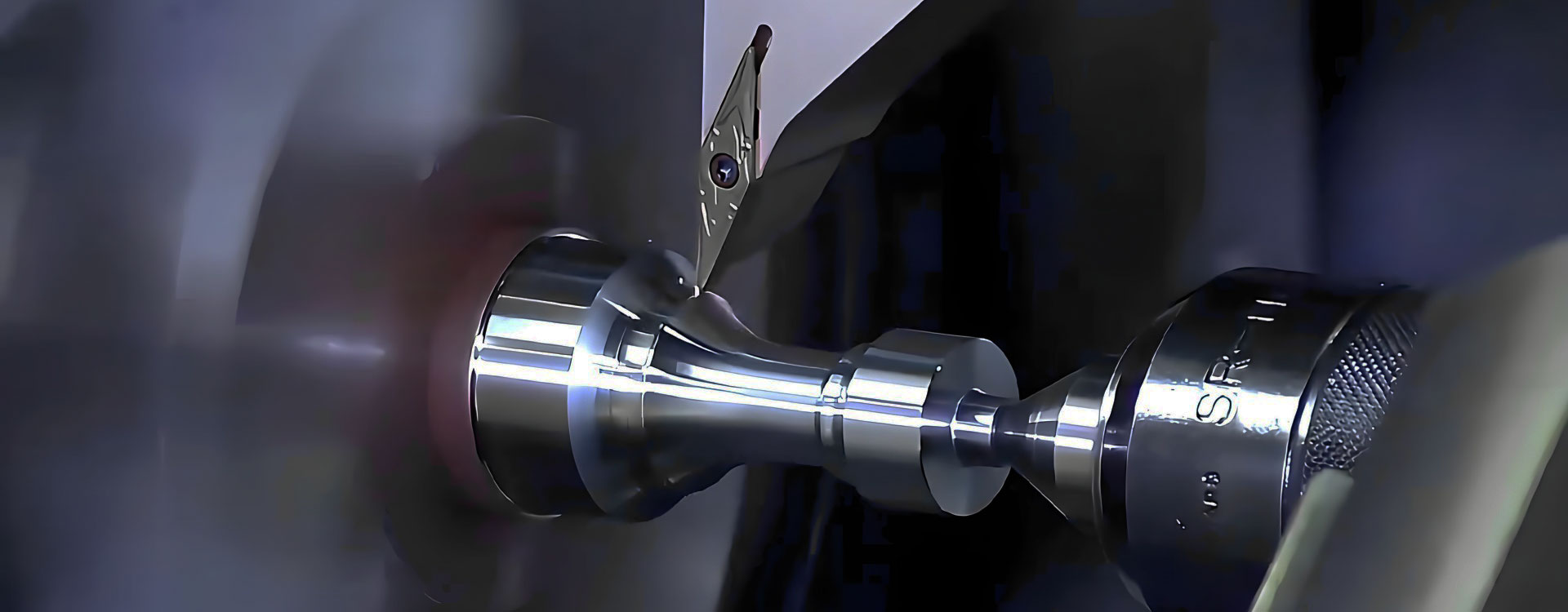

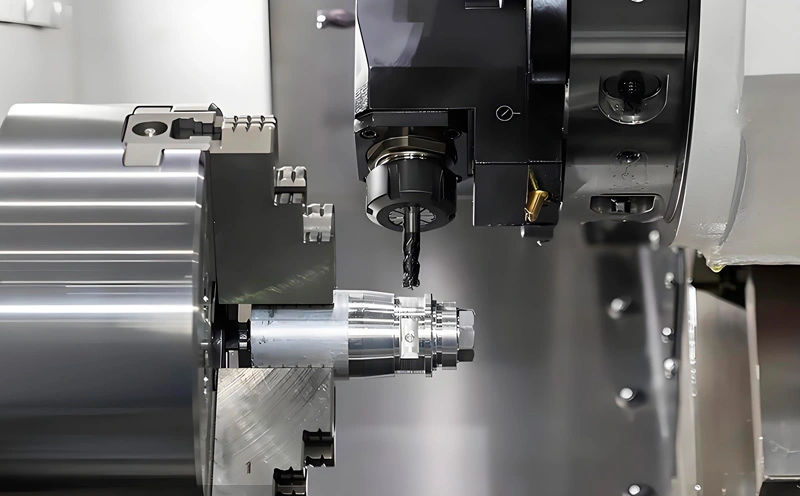

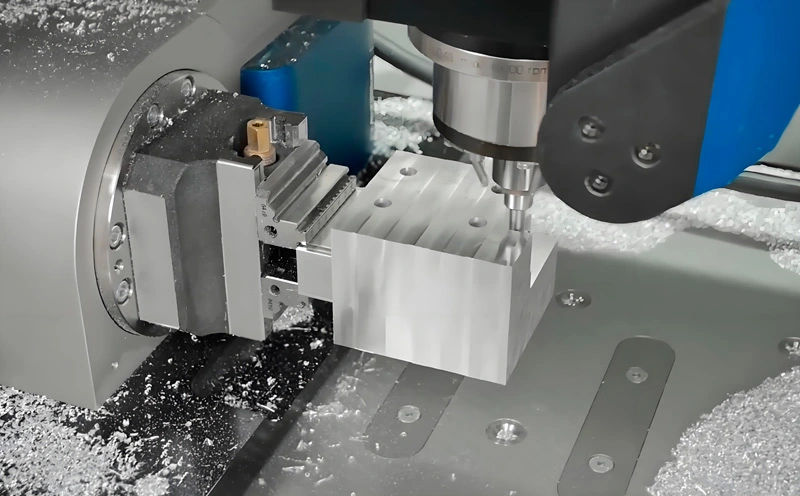

We have advanced CNC lathes and a professional technical team that can achieve micrometer level machining accuracy, ensuring precise product dimensions and smooth surfaces to meet your needs for high-quality parts.

The body, engine, and gearbox components require high-precision machining, and CNC lathe machining can ensure quality and durability.