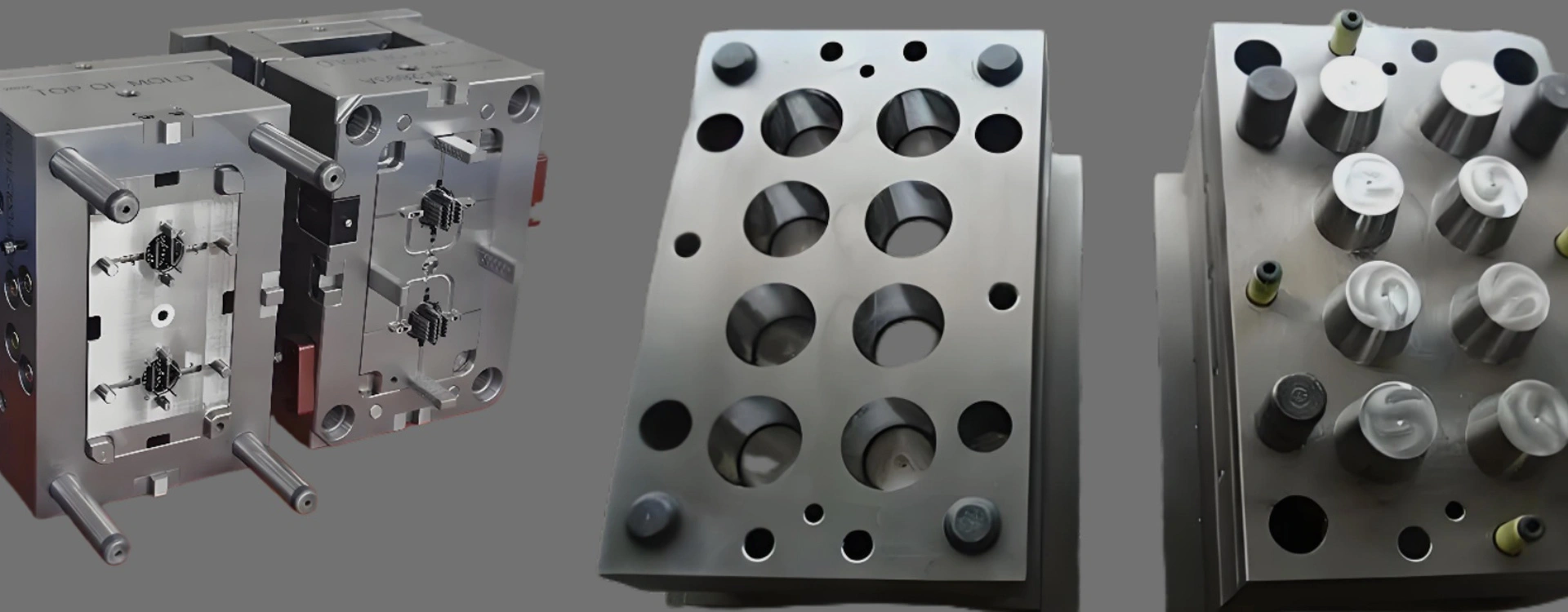

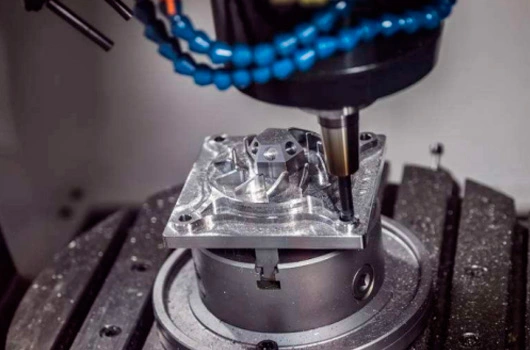

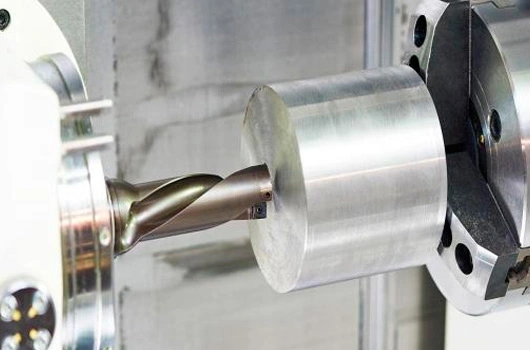

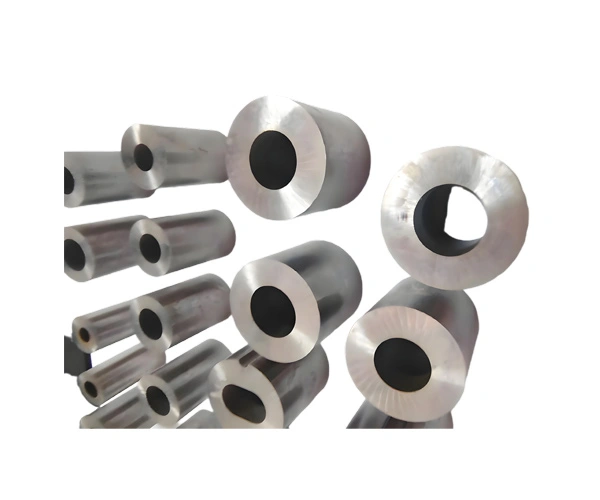

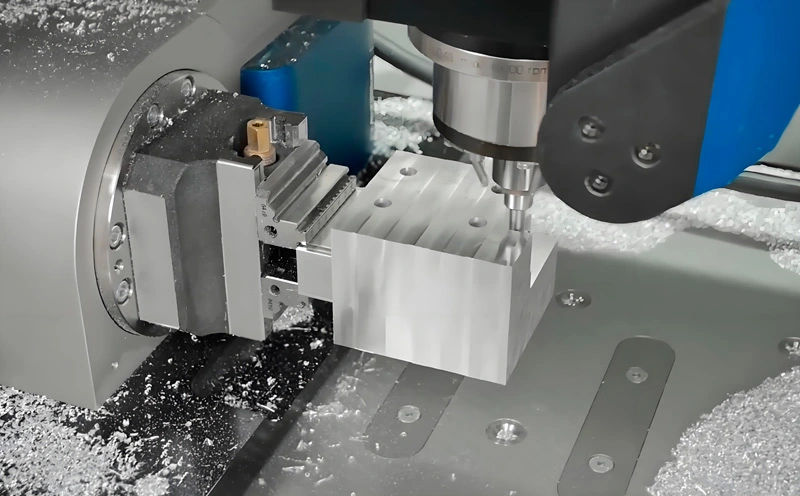

Milling is a cornerstone process for CNC mold parts. It can create complex cavities, cores, and parting surfaces. For instance, in injection mold making, milling precisely shapes the negative space for the molded product. Multi-axis milling machines enable intricate 3D geometries, like the detailed contours of a smartphone case mold.