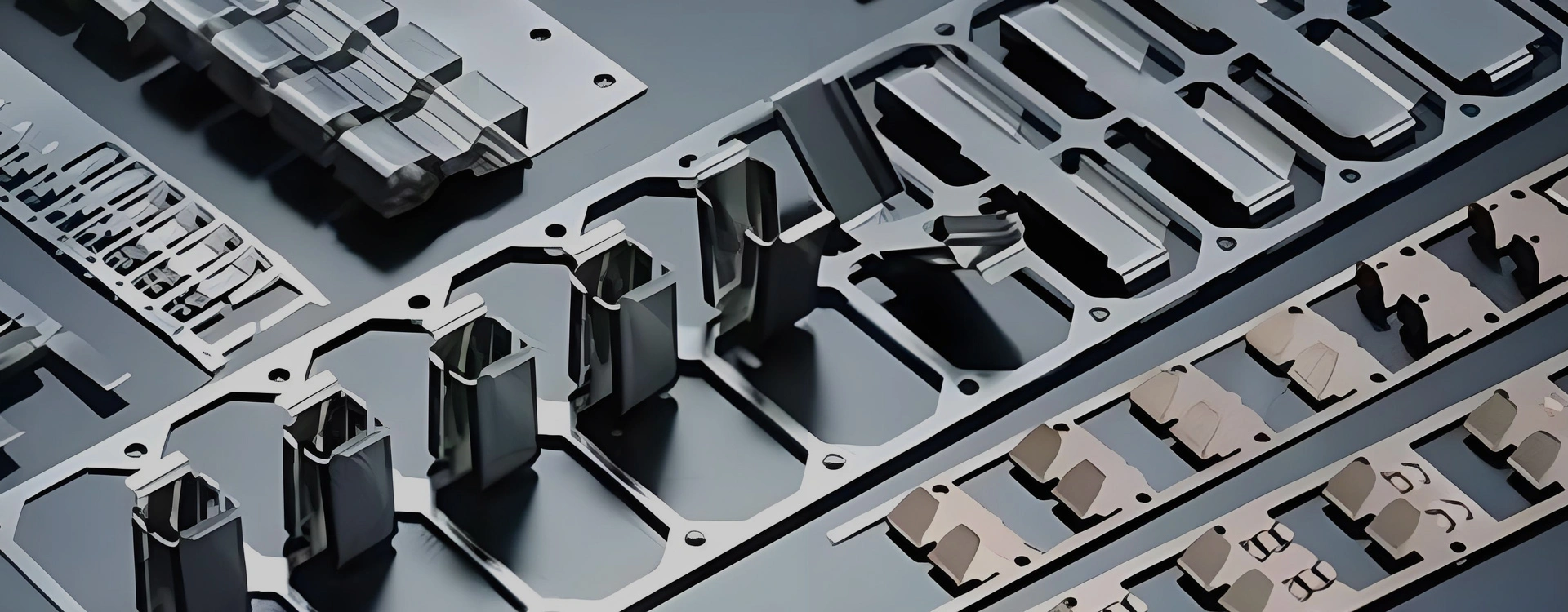

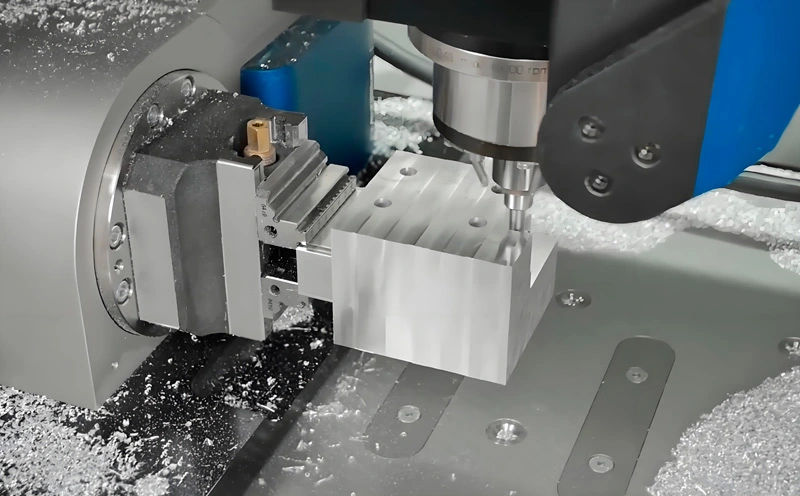

Our presses can handle parts up to 1 sq.m. Whether large or small, we meet your size needs precisely.

Our advanced stamping presses can handle metal parts up to 1 square meter in size. However, the exact size may vary depending on the thickness and type of metal.