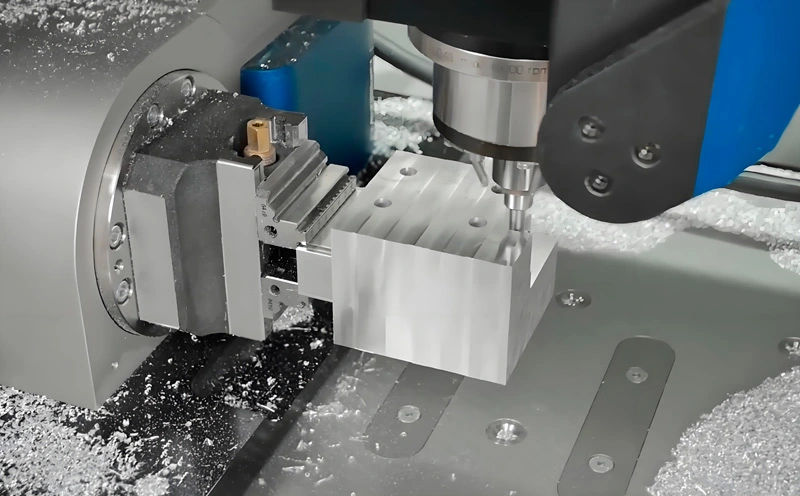

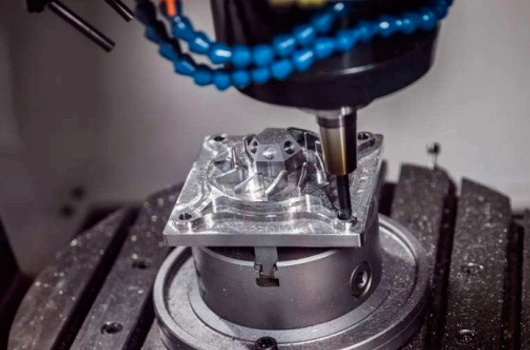

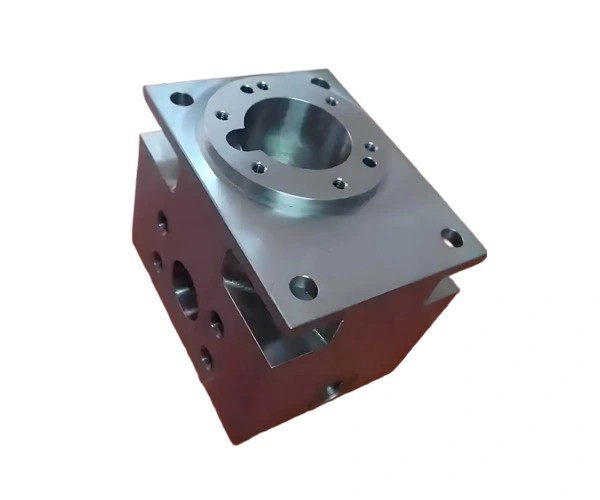

For CNC mechanical parts, we offer a comprehensive selection of materials. From robust steels like alloy 4140, providing excellent strength for heavy-duty applications, to lightweight aluminum alloys for components where weight matters. Our surface treatments enhance durability. Anodizing aluminum parts boosts corrosion resistance and wearability. For steel, options include nitride coating, which hardens the surface and reduces friction, ensuring your CNC mechanical parts perform optimally in diverse operating conditions.

What Kind of CNC Mechanical Parts can We Make?

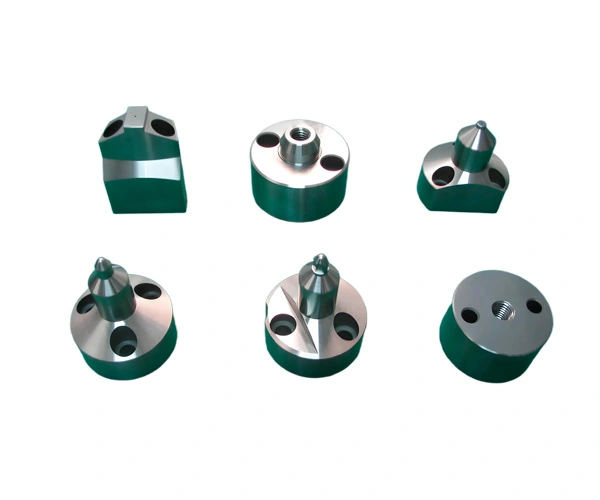

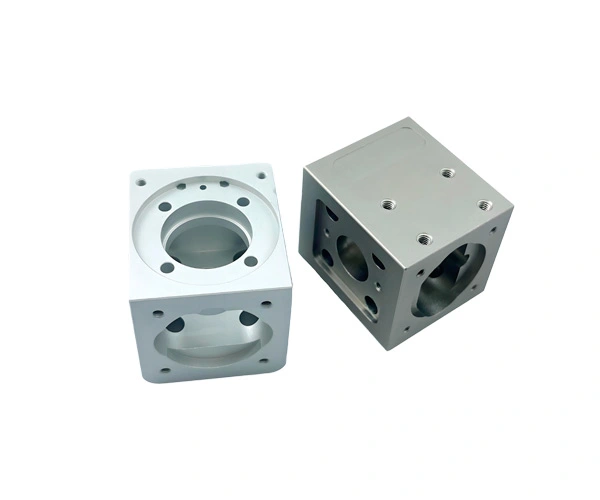

At MAXTECH CNC, we specialize in producing a comprehensive range of precision-machined CNC mechanics components to meet diverse industrial needs.

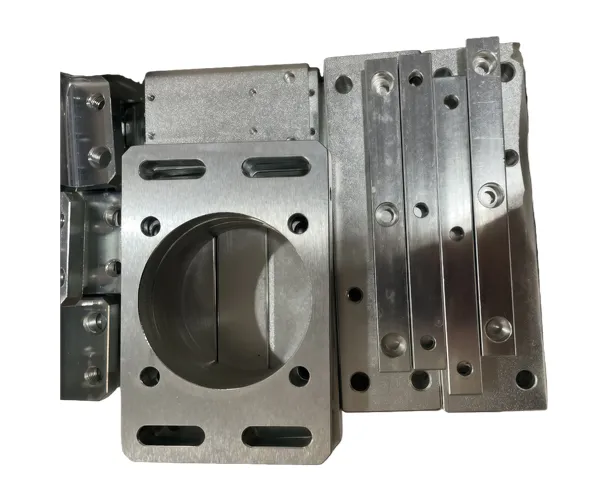

Structural and Support Components: Frames, brackets, plates, and mounting elements used in industrial equipment and machinery.

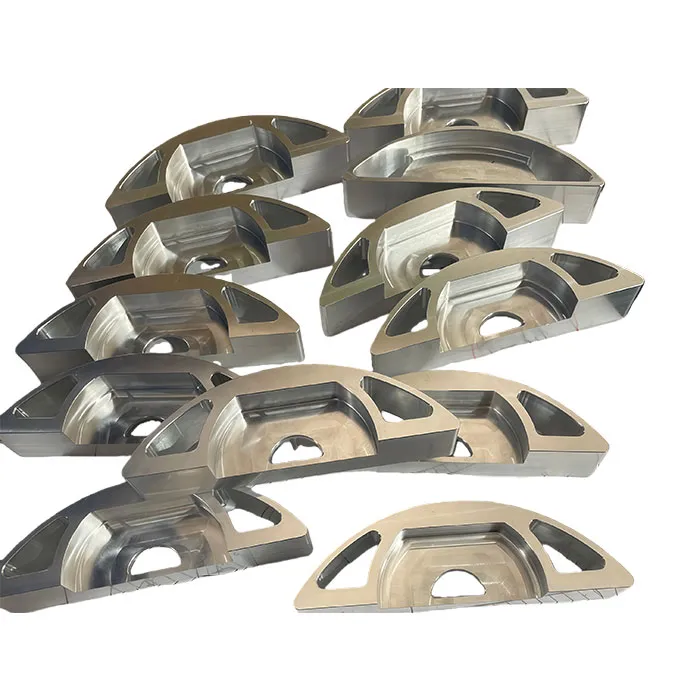

Rotating and Moving Parts: High-precision shafts, bushings, gears, couplings, and spindles for dynamic systems.

Functional Assembly Components: Pins, levers, mechanical linkages, and fasteners that ensure smooth motion and system reliability.

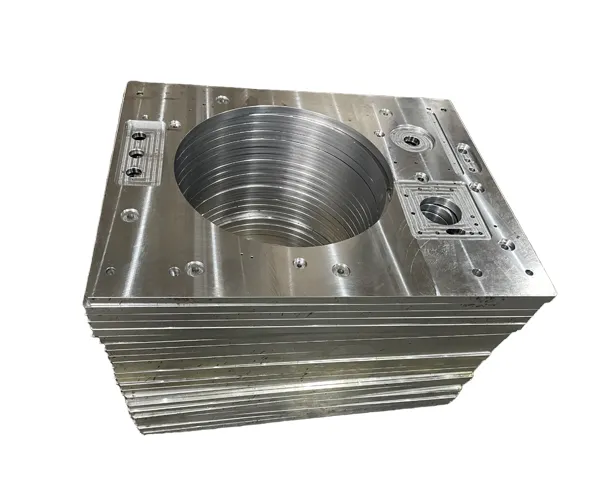

Housings and Enclosures: CNC-machined shells and covers for electronic systems, sensors, and mechanical assemblies.

Thermal Management Parts: Heat sinks, cooling plates, and other elements requiring fine surface finish and close tolerances.

Precision Inserts and Fixtures: Custom jigs, fixturing elements, and alignment parts used in assembly and production processes.

Custom OEM Parts: Tailor-made components based on customer CAD models for automotive, robotics, automation, and tooling applications.

.webp)

.webp)