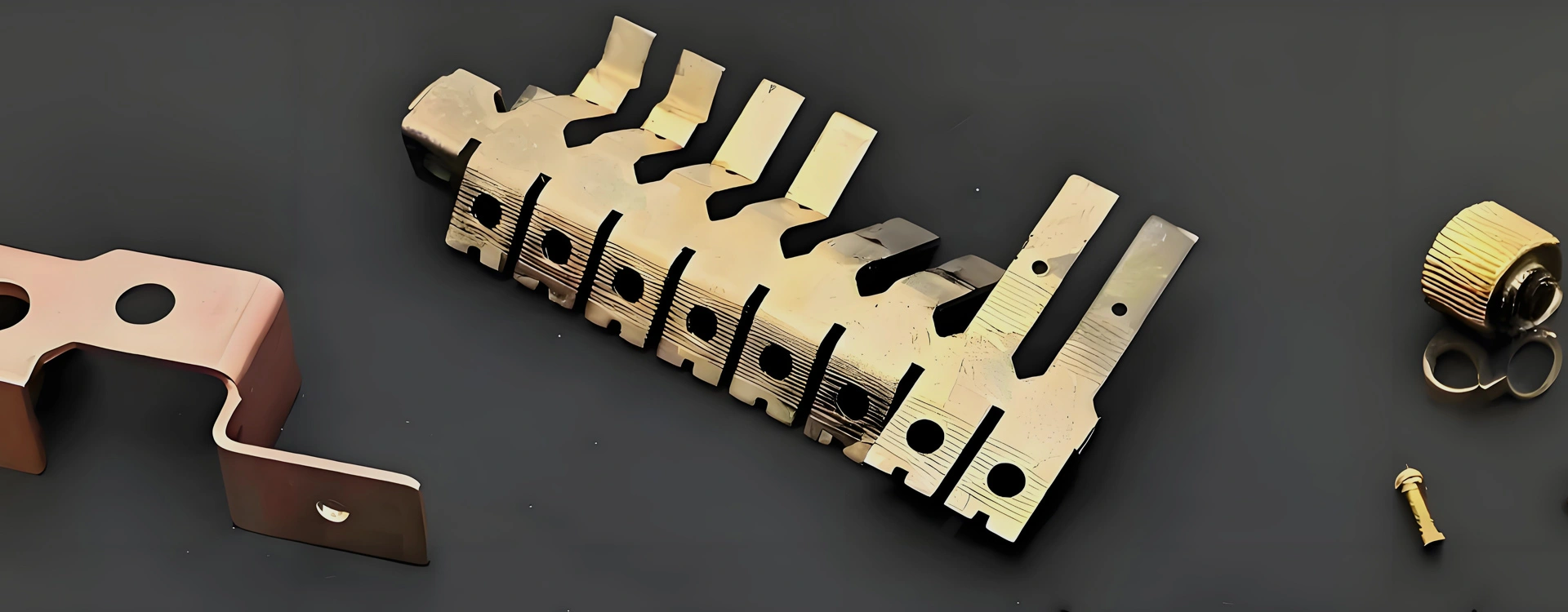

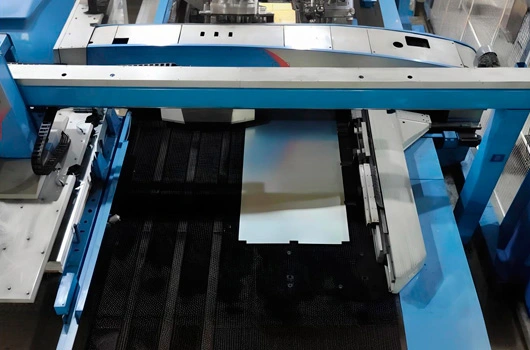

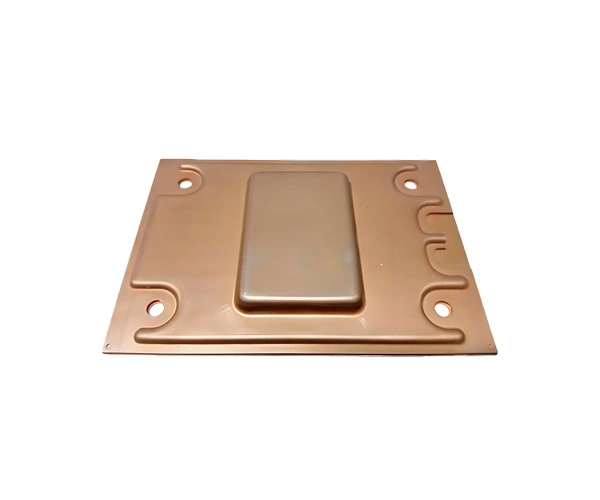

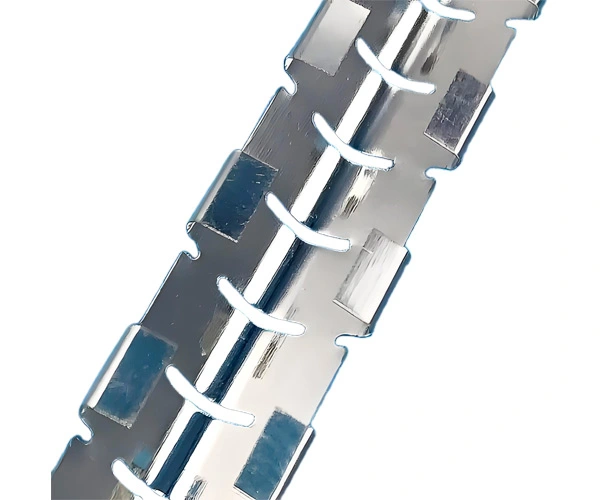

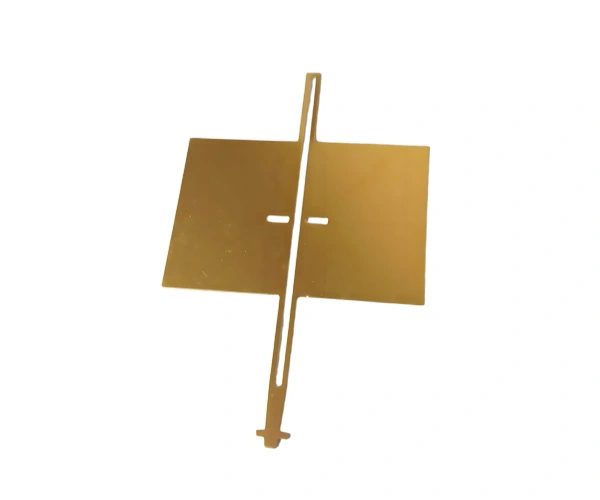

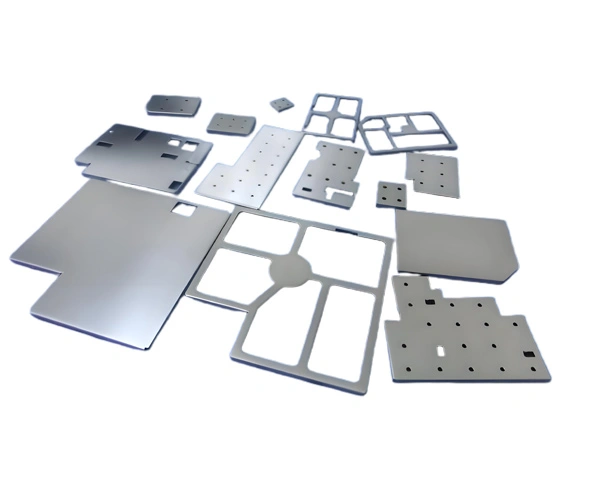

It's a basic process using dies to separate materials, which can directly make flat parts or prepare blanks for other processes. It includes blanking and punching, and is widely used in producing flat structural parts and perforated parts for communication equipment, like the outline blanking of mobile phone motherboards.