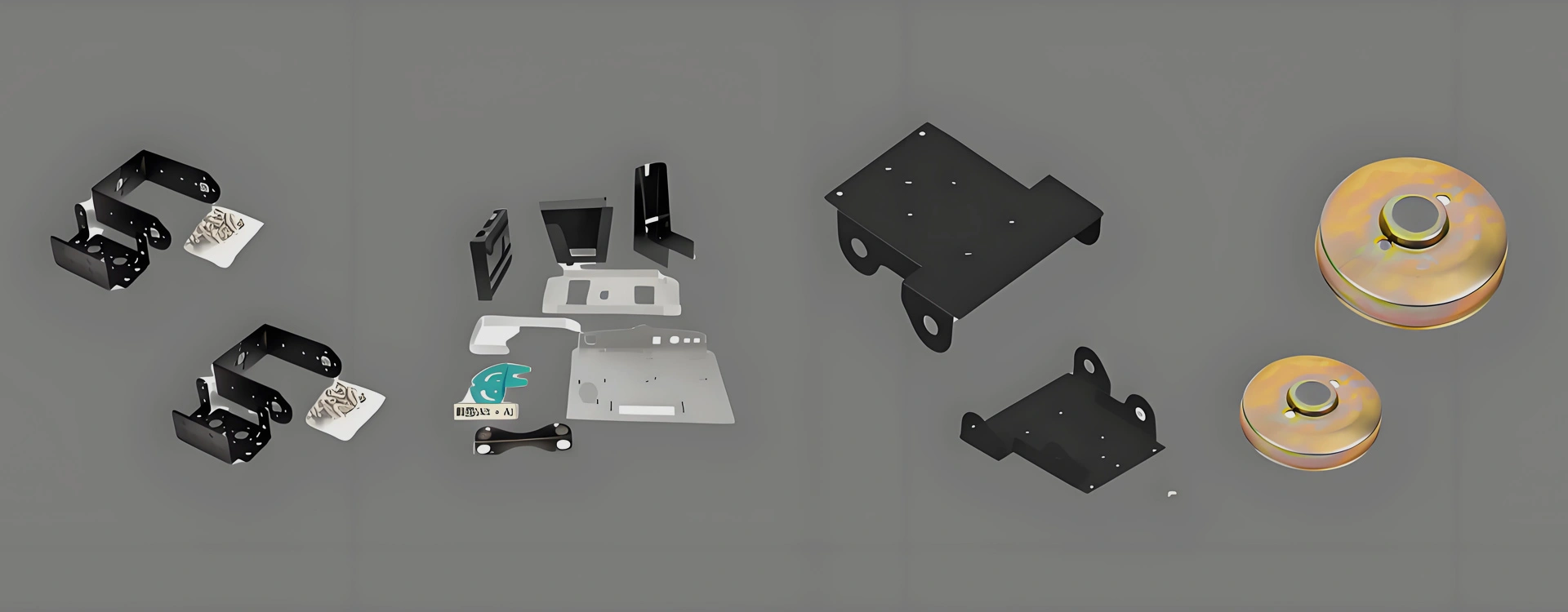

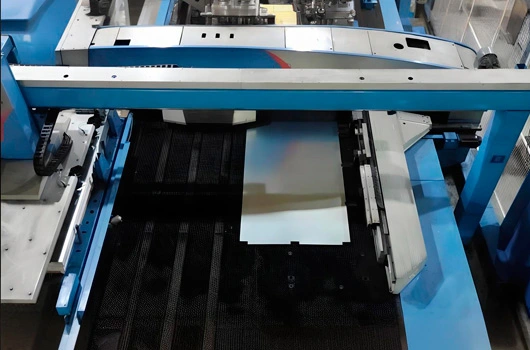

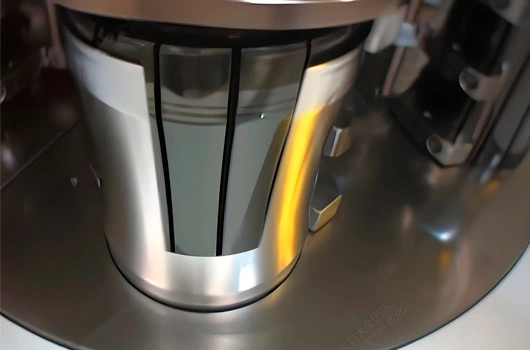

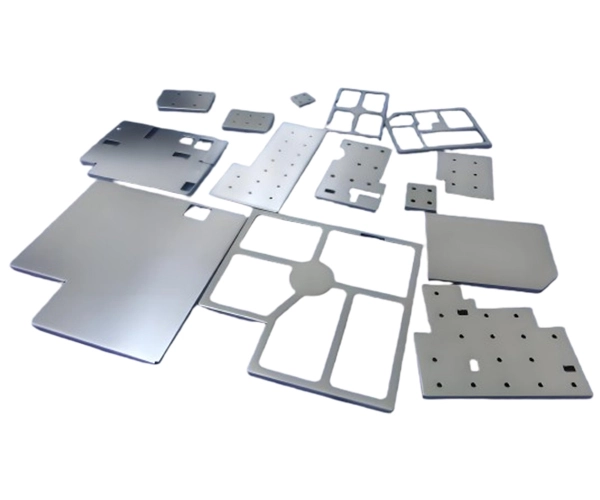

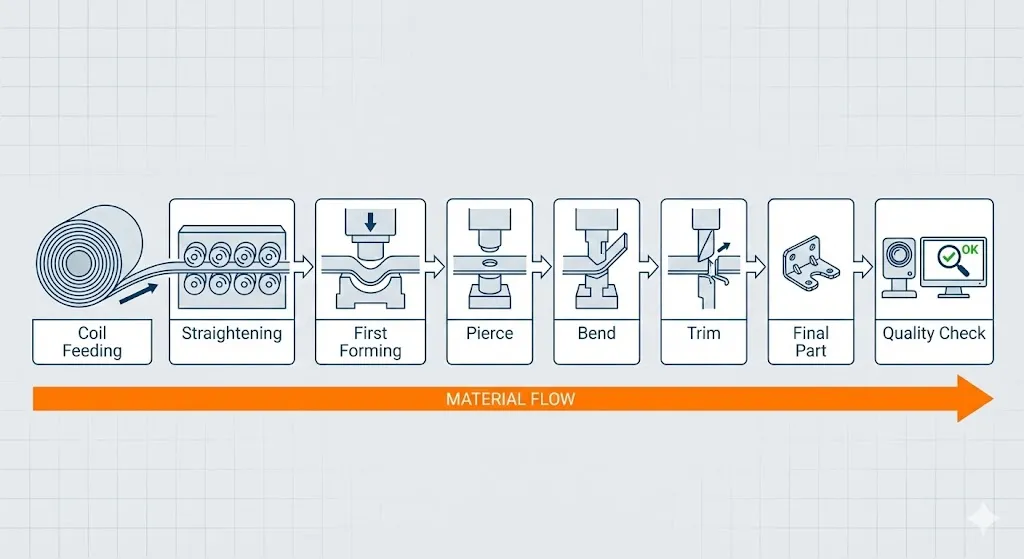

Industrial robots work with dies to separate the sheet metal along a closed contour, obtaining flat parts or open hollow parts. For example, the blanking of the outer shape of electronic device housings. It can efficiently produce parts with high precision and is widely used in industries such as electronics and automotive.