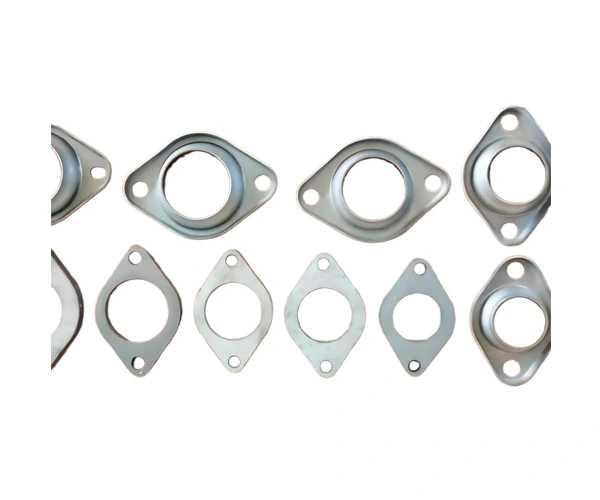

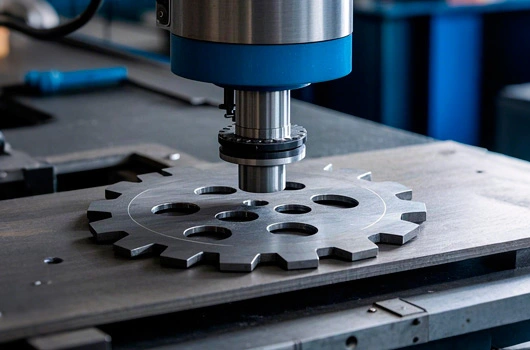

Separate materials through stamping dies to accurately obtain the contour of parts. Commonly used for manufacturing gears, gaskets, etc. Precision gears like those in mechanical watches rely on punching service to ensure accurate dimensions.

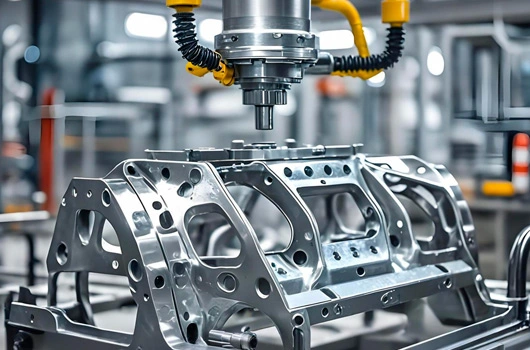

Our Stamping Mechanical Parts are the result of advanced manufacturing techniques. With a focus on precision and durability, we use high - quality materials. Each part is meticulously crafted to meet the demands of diverse mechanical applications, from industrial machinery to complex equipment. Whether it's for power transmission or structural support, our products are reliable choices.

Separate materials through stamping dies to accurately obtain the contour of parts. Commonly used for manufacturing gears, gaskets, etc. Precision gears like those in mechanical watches rely on punching service to ensure accurate dimensions.

Bend the board into a specific angle or shape to meet different mechanical structural requirements. For example, the connecting parts of the crane arm are often formed through bending service.

Pulling flat blanks into hollow shapes, such as the oil pan of a car engine, is a typical product of stretching technology.

Create complex shapes, such as mechanical casings. By stamping once or multiple times, give the parts a unique appearance and structure.

In the manufacturing of mechanical components, metal stamping technology has significant advantages. It can achieve high-precision machining, ensuring precise matching of part dimensions. With the help of molds, mass production can be achieved, greatly reducing costs. High production efficiency, able to quickly meet market demand. In addition, it can also manufacture parts with diverse shapes to meet various complex mechanical design requirements.