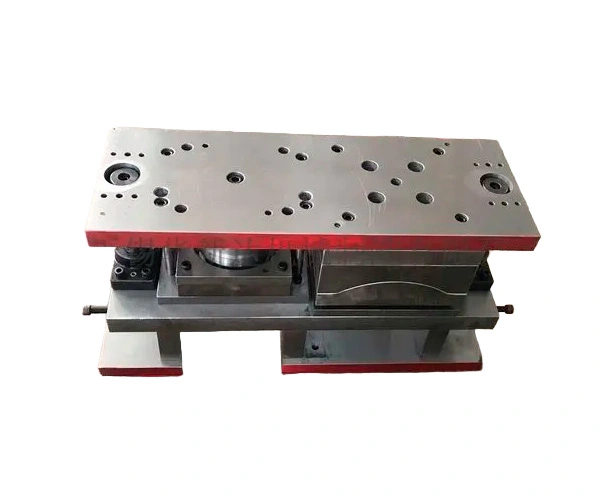

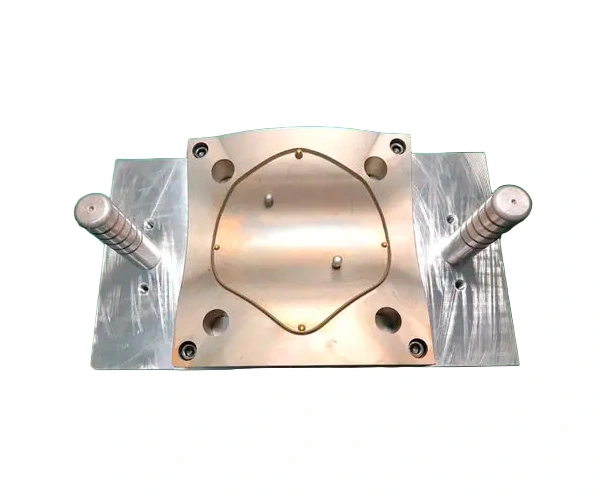

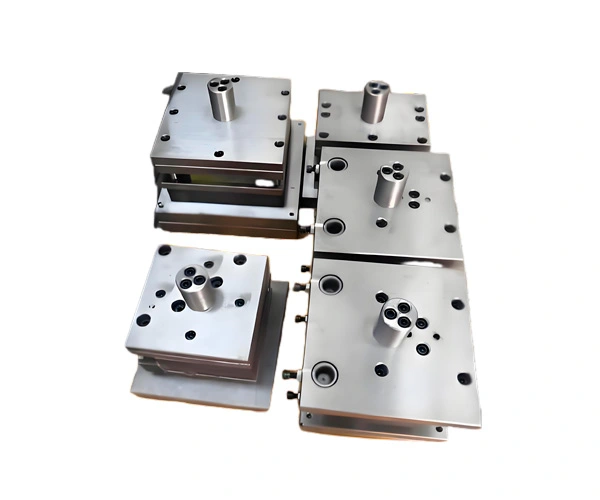

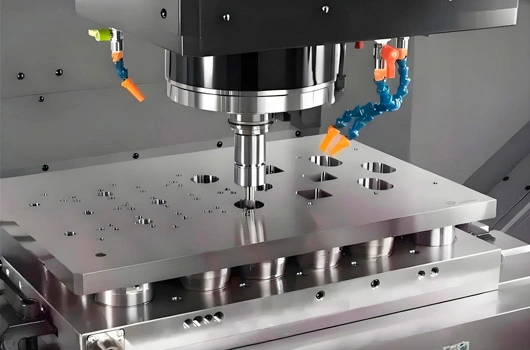

Stamping is carried out at room temperature, and the material is subjected to plastic deformation using a mold. Commonly used for manufacturing small precision mold parts, such as inserts in electronic molds.

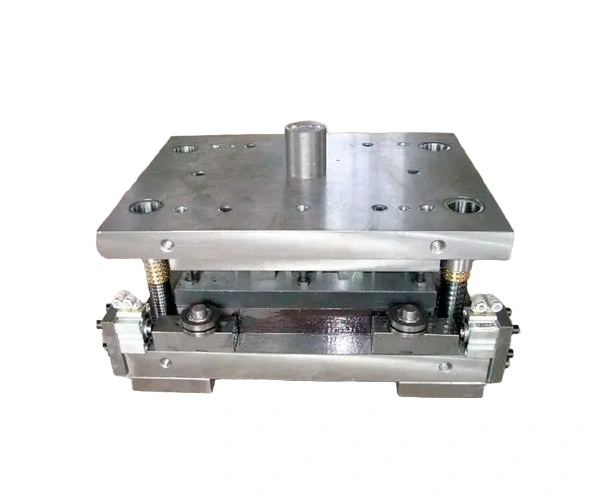

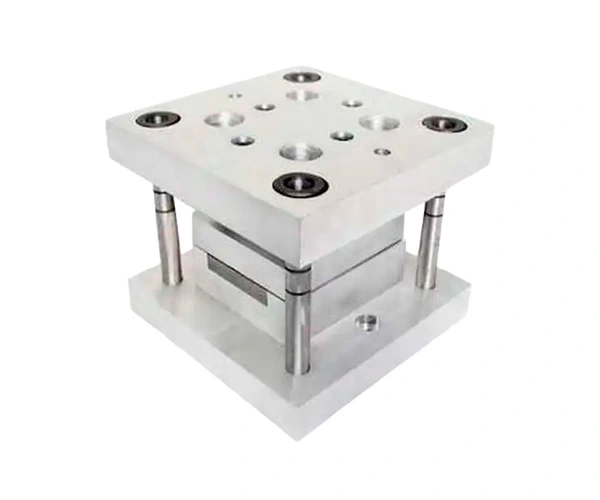

Our Stamping Mold Die Parts are a cut above the rest. Engineered with state-of-the-art techniques, they exhibit exceptional precision. Made from premium materials, these parts guarantee long-lasting performance. They are the backbone of efficient stamping processes, fitting seamlessly into various industrial applications.

Stamping is carried out at room temperature, and the material is subjected to plastic deformation using a mold. Commonly used for manufacturing small precision mold parts, such as inserts in electronic molds.

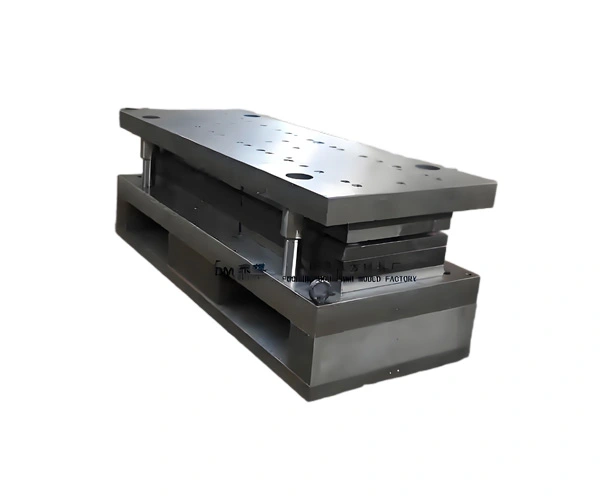

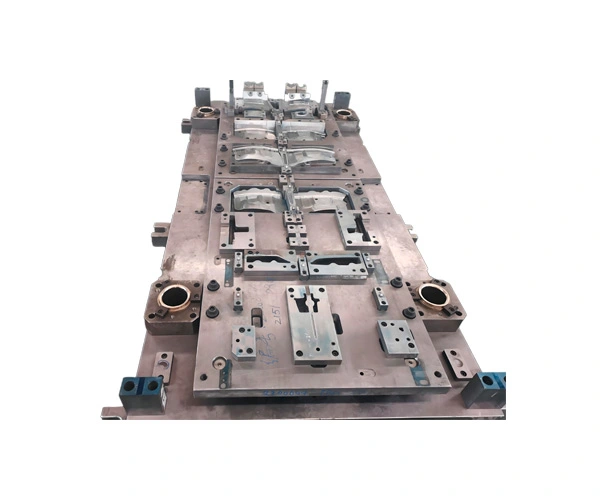

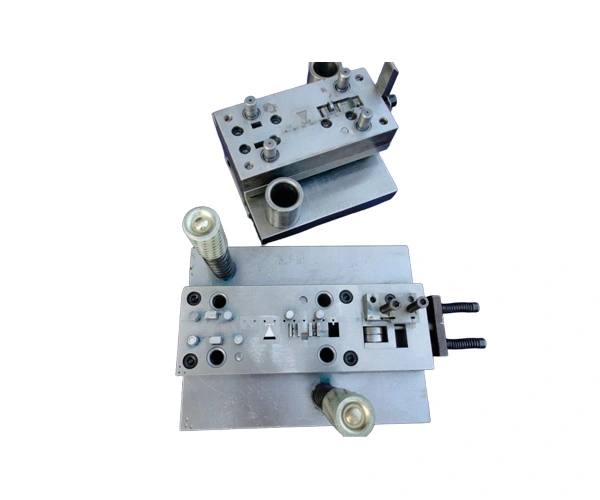

By using multi station molds, multiple processes can be completed in one stamping stroke. Can efficiently produce a large number of identical mold parts, such as positioning pins for standard molds.

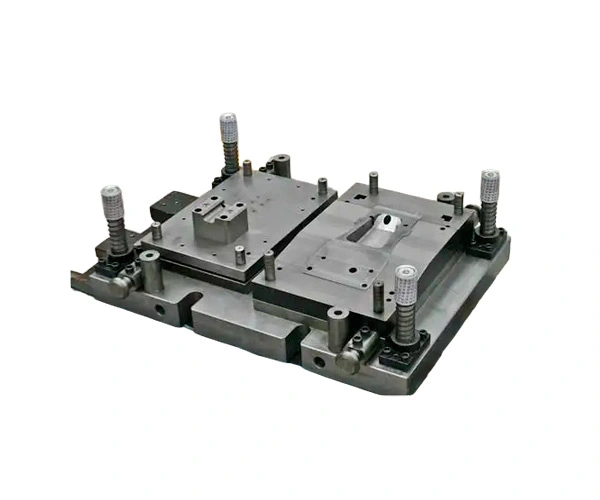

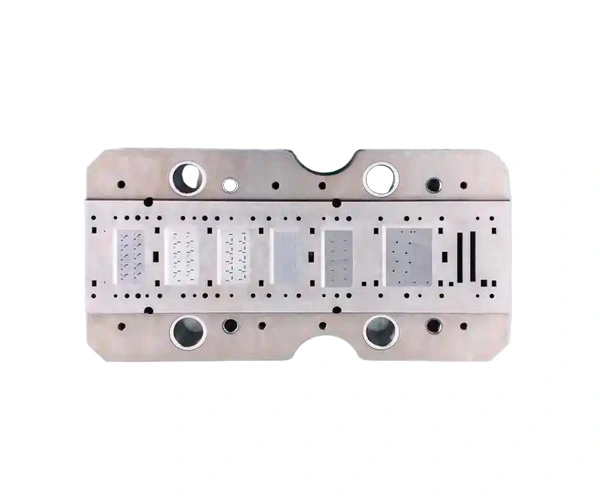

Simultaneously completing multiple stamping processes at the same workstation, such as cutting and punching. Commonly used for manufacturing structurally complex mold parts, such as mold templates.

There are many reasons why metal stamping technology is used in the manufacturing of mold components. It can achieve high-precision machining, ensure the precise size of mold parts, and guarantee the overall performance of the mold. During mass production, it can effectively control costs and improve economic efficiency. At the same time, the efficiency of stamping technology can quickly produce a large number of parts, meet market demand, and help the efficient development of the mold manufacturing industry.