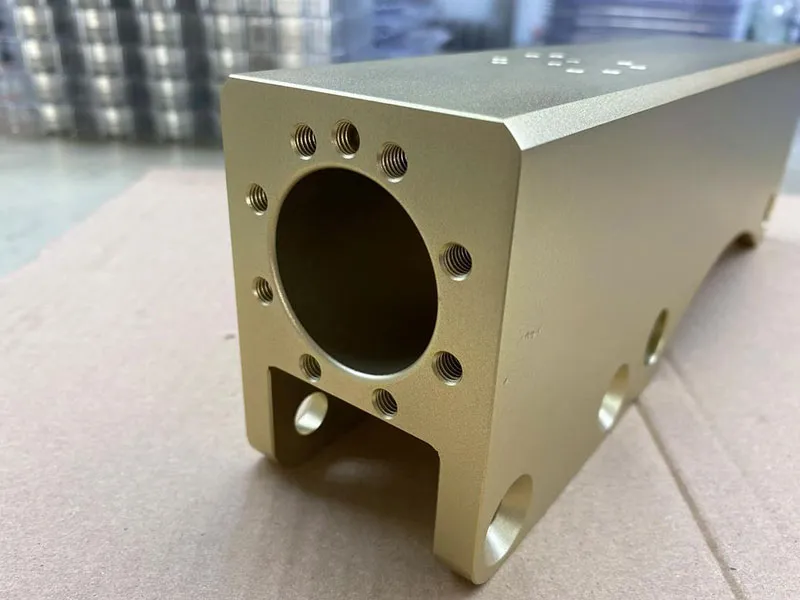

Surface finishing is a critical part of precision manufacturing that defines product quality, functionality, and appearance at MAXTECH. From aluminum anodizing and stainless-steel polishing to powder coating, plating, and sandblasting, we offer a comprehensive range of CNC surface finish solutions tailored to meet the exact requirements of every project.

Our expert team ensures that each part not only meets dimensional tolerances but also achieves the desired surface texture, corrosion resistance, and visual aesthetics. Whether for aerospace, automotive, medical, or electronic applications, MAXTECH delivers consistent, high-quality surface finishes that enhance both performance and durability.

Our stainless steel surface treatment services include sandblasting, polishing, passivation, and spray painting, with excellent rust prevention and anti pollution performance. Commonly found in the fields of decoration, home appliances, kitchenware, etc.

Brass surface treatment: electroplating, powder coating, polishing, passivation

Copper surface treatment: passivation, anodizing, polishing, electroplating, nickel plating

Surface finish directly affects the appearance, functionality, and longevity of machined parts. A well-chosen finish can reduce friction, prevent corrosion, and improve assembly fit. In precision manufacturing, even minor deviations in surface roughness can impact part performance.

At MAXTECH, we integrate surface finishing into both CNC machining and metal stamping workflows. This ensures consistent quality from prototype to mass production, allowing for a seamless transition from raw machining to the final treated surface.

Different industries require different finishes, from satin and matte looks for industrial tools to high-gloss coatings for consumer electronics. Our finishing processes not only improve the mechanical properties but also elevate the visual value of each product.

Surface finish quality is typically expressed in Ra (Roughness Average) values. Lower Ra means smoother surfaces. CNC-machined parts often achieve Ra values as low as 0.2–0.8 μm, depending on the cutting tools and finishing method.

MAXTECH follows strict ISO-based quality control procedures. Each part is inspected using precision measurement tools to ensure it meets dimensional, visual, and performance standards.

Our engineers assist clients in reviewing and optimizing technical drawings for accurate results. To achieve the desired finish, customers should clearly specify:

Ra or gloss level

Finishing process (e.g., anodized Type II, sandblasted matte)

Tolerances and masking areas

At MAXTECH, we manage the entire process under one roof, from CNC machining or stamping to surface finishing. This integration eliminates delays and ensures consistent results for every production batch.

Whether producing a single prototype or high-volume parts, MAXTECH guarantees uniform finish quality through strict inspection and advanced process control systems. Our surface finishes are widely used in:

1. Automotive industry

Body/exterior components: spray painted, chrome plated.

Chassis/structural components: hot-dip galvanized (high-strength anti-corrosion).

2. 3C Electronics Industry

Shell/decorative parts: anodizing, sandblasting.

Internal conductive components: electroplated copper/silver, electroless nickel plating.

3. Mechanical manufacturing industry

Transmission components (gears, shafts): quenched, blackened.

Hydraulic components/valves: chrome plated

4. Construction industry

Doors and windows/curtain walls (aluminum alloy): anodizing, powder coating.

Steel structure: galvanized, painted.

5. Medical device industry

Surgical instruments: electrolytic polishing, passivation

Shell/bracket: sprayed with antibacterial coating, anodized

6. Furniture and Home Furnishing Industry

Metal frame: powder coating, electroplating

Hardware accessories: galvanized